PART 3: LEAN SIX SIGMA ACROSS INDUSTRIES

13 Chapter 13: Lean Six Sigma in Government and Non-Profit

Learning Objectives

- Understand the role of Lean Six Sigma in improving efficiency and effectiveness in public and non-profit organizations.

- Identify the unique challenges and constraints of implementing Lean Six Sigma in government and non-profit settings.

- Apply Lean Six Sigma tools to streamline service delivery and optimize resource allocation.

- Analyze case studies demonstrating successful Lean Six Sigma initiatives in the public and non-profit sectors.

- Develop strategies to engage stakeholders and measure the return on investment (ROI) for Lean Six Sigma projects in these environments

Introduction

Lean Six Sigma, a methodology combining the waste-reduction principles of Lean with the variability-reduction focus of Six Sigma, has gained traction in the government and non-profit sectors. This chapter explores how these methodologies can drive significant improvements in public sector and non-profit organizations, addressing their unique challenges and opportunities.

As the public sector and non-profits face increasing pressure to do more with less, Lean Six Sigma offers a structured approach to improve efficiency, reduce waste, and enhance service quality. We will examine strategies for streamlining processes, enhancing transparency and accountability, and driving operational excellence in environments with complex regulatory requirements, limited resources, and diverse stakeholder expectations. Table 1 identifies the key quality tools for both the public and non-profit entities.

| Component | Description | Example |

| Customer Focus | Prioritizing the needs and expectations of the public and stakeholders to improve service delivery and satisfaction | Reducing waiting times at public service offices to enhance citizen satisfaction |

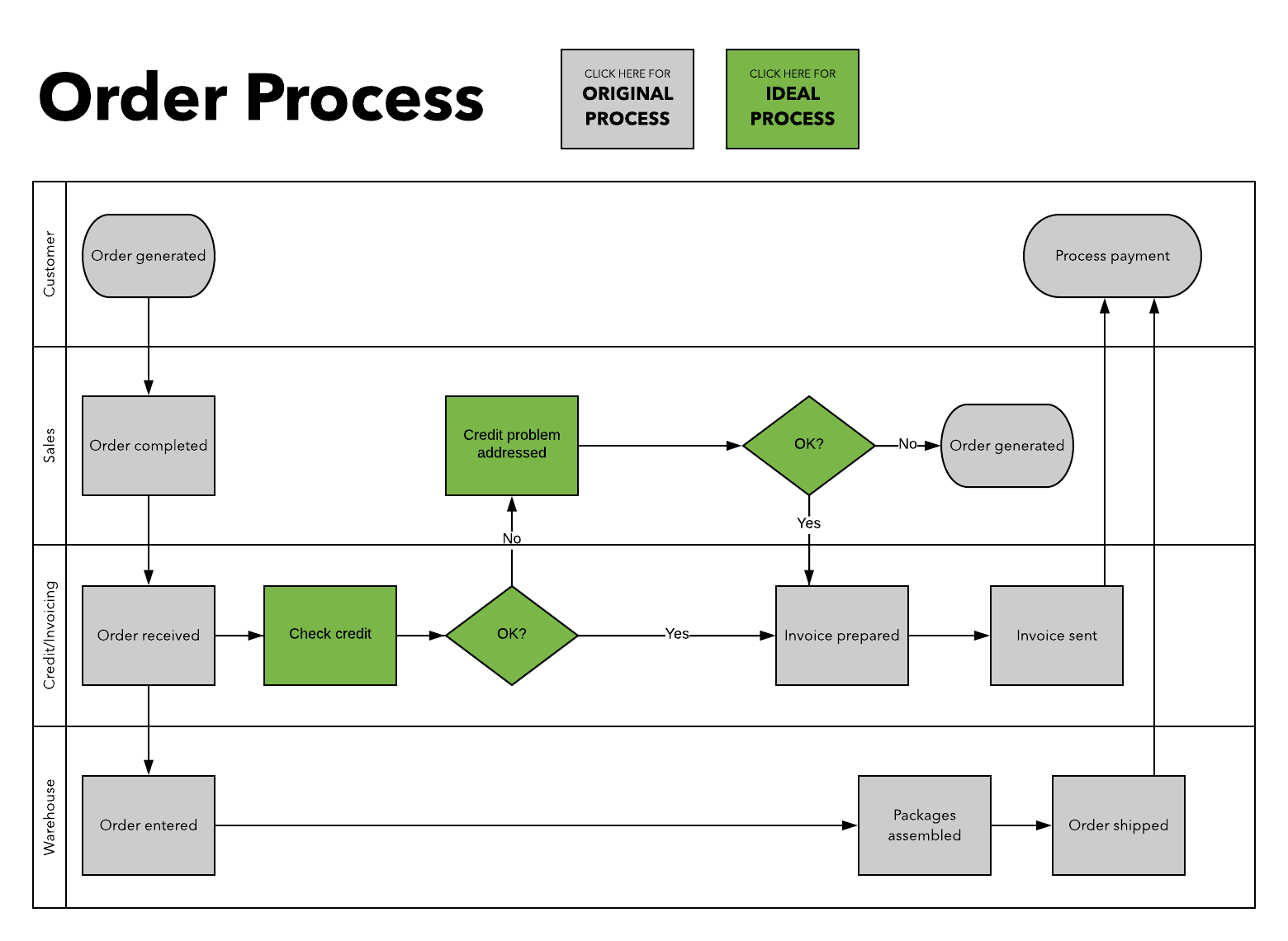

| Process Mapping | Visualizing and understanding current processes to identify inefficiencies and areas for improvement | Mapping the steps in a permit application process to identify bottlenecks and delays |

| DMAIC Methodology | A structured approach to problem-solving and process improvement consisting of Define, Measure, Analyze, Improve, and Control | Improving response times for emergency services by analyzing current procedures and implementing changes |

| SIPOC Diagram | A tool used to identify Suppliers, Inputs, Process, Outputs, and Customers, providing a high-level view of a process | Creating a SIPOC diagram for the public transportation system to understand the entire process, from planning routes to delivering services |

| Root Cause Analysis | Identifying the underlying causes of problems to address them effectively and prevent recurrence | Using a fishbone diagram to determine the root causes of high employee turnover in a government department |

| Statistical Analysis | Applying statistical tools to analyze data and measure performance, variability, and improvement | Analyzing crime data to identify trends and allocate police resources more effectively |

| Lean Tools (5S, Kaizen) | Implementing Lean techniques such as 5S (Sort, Set in order, Shine, Standardize, Sustain) and Kaizen (continuous improvement) to streamline processes and eliminate waste | Applying 5S in a public library to organize materials and improve efficiency |

| Benchmarking | Comparing performance metrics to best practices and standards to identify areas for improvement | Benchmarking the efficiency of local healthcare services against leading national hospitals |

| Training and Development | Providing employees with the skills and knowledge they need to implement Lean Six Sigma principles effectively | Conducting Lean Six Sigma training workshops for public sector employees to foster a culture of continuous improvement |

| Change Management | Managing the human side of change to ensure successful implementation of new processes and improvements. | Implementing a change management plan to support the transition to a new digital records system in a government office |

| Performance Metrics | Establishing key performance indicators (KPIs) to measure progress and impact of improvements | Setting KPIs for processing times of public assistance applications and tracking performance against these benchmarks |

| Stakeholder Engagement | Involving stakeholders in the improvement process to ensure their needs are met and to gain support for changes. | Engaging community leaders and residents in a project to improve public transportation services |

| Cost-Benefit Analysis | Evaluating the financial implications of improvement projects to ensure they provide value for cost and they are financially viable | Conducting a cost-benefit analysis of digitizing public records to determine the long-term savings versus the initial investment |

| Sustainability | Ensuring that improvements are maintained over time and continue to deliver benefits | Establishing a monitoring system to ensure continued compliance with new waste reduction practices in municipal operations |

By incorporating these components, public sector organizations can enhance their efficiency, reduce waste, improve service delivery, and achieve better outcomes in the communities they serve.

Streamlining Processes and Improving Efficiency in the Public Sector

Identifying Waste in Government Processes

Identifying waste in government processes is crucial for optimal efficiency and service delivery. By addressing inefficiencies like over-processing, waiting, and unnecessary motions, governments can allocate resources more effectively. This approach leads to cost savings and improves public services. This focus on efficiency fosters accountability and transparency, and it builds public trust, and encourages innovation within agencies. Ultimately, reducing waste enables governments to better serve their communities and adapt to changing needs. Dr. Jimmy Gray

In the public sector, waste can manifest as:

- Over-processing: Unnecessary paperwork or approvals

- Waiting: Delays in service delivery or decision making

- Transportation: Inefficient movement of documents or people

- Inventory: Excess stockpiling of supplies or information

- Motion: Inefficient layouts or workflows

- Defects: Errors in documentation or service delivery

- Overproduction: Creating reports or services that aren’t needed

Tools like Gemba walks and Value Stream Mapping (VSM) are critical for identifying these wastes (Maleyeff, 2007).

Gemba walks involve going to the place where the “actual work” occurs. By observing processes firsthand and engaging with employees, decision makers can identify inefficiencies, redundancies, and areas where value is not added. This direct observation may reveal issues that are not be apparent in reports or meetings, and it fosters a culture of continuous improvement.

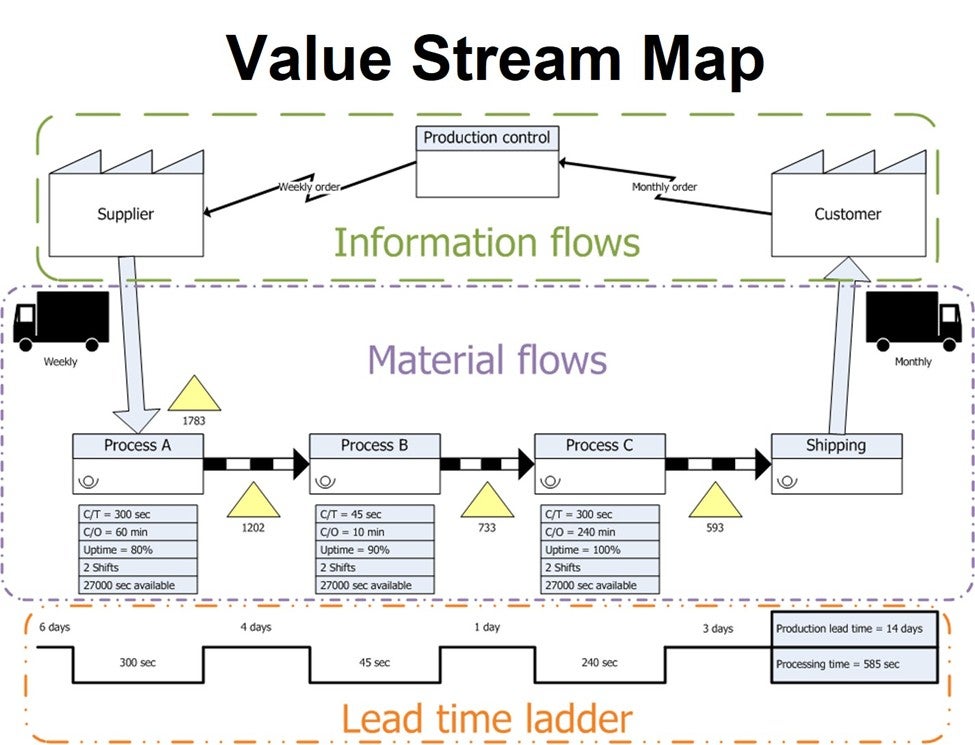

Value Stream Mapping is a visual tool that outlines all steps in a process from start to finish. It helps teams visualize the flow of information and materials, and VSM may pinpoint waste, such as waiting times, excess motion, and over-processing. By analyzing the current state of processes, teams can identify opportunities to streamline processes and enhance efficiency.

In summary, Gemba walks and Value Stream Maps are invaluable tools for identifying waste in government processes, thus enabling agencies to enhance efficiency and service delivery. The next section of this book will delve deeper into various mapping tools, including process mapping and value stream mapping. These tools provide structured approaches to visualize workflows and analyze processes, and this will equip learners with the knowledge and techniques necessary to understand and improve their operations. In the following section will explore the use mapping tools to further refine and optimize processes for better outcomes (see Chapter 3 for more details on Value Stream Mapping).

Examples of Process Mapping and Value Stream Analysis

Process mapping and VSM are essential for understanding and improving government processes. The U.S. Army used VSM to improve its recruitment process, reducing the time from initial contact to enlistment by 40%, and this time reduction demonstrates the power of these tools (George, 2003).

EPA Office of Pesticide Programs Antimicrobial Testing Program VSM

Implementing Lean Tools in Government Settings

This section will explore the transformative potential of Lean tools within government settings. By embracing methodologies such as 5S, Kaizen events, standard work, and visual management, public sector organizations can significantly enhance their operational efficiency and service quality. These tools not only streamline processes but also cultivate a culture of continuous improvement, empowering employees to identify and eliminate waste. As this chapter delves into practical applications and real-world examples, readers will discover how these Lean principles can lead to more effective governance and more responsive public service. Lean tools can help to realize the full potential of public sector organizations. ~ Dr. Jimmy Gray

Effective Lean tools in government settings include:

- 5S (Sort, Set in order, Shine, Standardize, Sustain)

- Kaizen Events

- Standard Work

- Visual Management

Case Studies: Successful Process Improvements

- City of Irving, Texas: Reduced building permit approval time by 40% (Furterer, 2016)

- U.S. Environmental Protection Agency: Reduced state implementation plan review time from 18 to 6 months (EPA, 2009)

- UK National Health Service: Improved patient flow and reduced waiting times in emergency departments (Mazzocato et al., 2012)

Enhancing Transparency and Accountability

The Importance of Transparency in Government

Lean Six Sigma offers a transformative approach to transparency and accountability in government. LSS simplifies complex processes and establishes clear metrics, and it provides a framework for measurable success. Real-time tracking of service delivery and project status further empowers agencies to respond swiftly to community needs. This section explores how these principles can make government operations more efficient and responsive. ~ Dr. Jimmy Gray

Lean Six Sigma enhances transparency in the following ways:

- Simplifying complex processes

- Providing clear metrics and performance indicators

- Enabling real-time tracking of service delivery and project status

The Scottish Government’s redesign of its freedom of information process exemplifies this approach.

Using Six Sigma for Data-driven Decision Making

Implementing performance metrics and scorecards before beginning Six Sigma to inform data-driven decision making is an essential step.

- Foundation of Understanding: Performance metrics and scorecards lay the groundwork for understanding how to measure success. They provide a clear overview of what to track, and they make the subsequent introduction of Six Sigma more meaningful.

- Alignment with Goals: Before applying Six Sigma, it is vital to define what the organization aims to achieve. Metrics clarify these goals and ensure that Six Sigma initiatives align with them.

- Data-driven Context: By discussing performance metrics beforehand, individuals will better understand the context and importance of data in decision making. This sets the stage for explaining the ways in which Six Sigma’s data-driven approach is necessary.

- Enhanced Engagement: Individuals may find it easier to engage with Six Sigma concepts if they see how metrics and scorecards will be used in practice. This can illustrate the value of Six Sigma in enhancing performance.

- Step-by-Step Approach: There is a logical progression from metrics to Six Sigma that allows learning to proceed step by step, something helps individuals in absorbing knowledge and applying it effectively.

In summary, starting with performance metrics and scorecards creates a strong foundation for understanding and practicing Six Sigma.

Six Sigma’s data-driven approach aligns with government accountability needs using the following tools:

- Collecting and analyzing data to identify root causes

- Using statistical tools to validate improvement efforts

- Developing evidence-based policies and programs

The City of Fort Wayne, Indiana optimized its garbage and recycling routes and demonstrates this principle (George, 2003).

Implementing Performance Metrics and Balanced Scorecards

The Balanced Scorecard (BSC) is a strategic management tool that measures organizational performance across four areas: Financial, Customer, Internal Processes, and Learning & Growth. It provides a comprehensive view of business performance and helps organizations align their activities with their vision and strategy.

BSC and Lean Six Sigma (LSS) combined are a powerful framework for enhancing performance in the areas below:

- Financial: LSS projects improve profitability by reducing costs and directly impacts financial metrics.

- Customer: LSS enhances customer satisfaction through better quality and quicker delivery and aligns with customer-focused BSC goals.

- Internal Processes: LSS targets process inefficiencies that the BSC can prioritize based on strategic objectives.

- Learning & Growth: LSS supports continuous improvement and promotes employee development aligning with the BSC growth goals.

This integration ensures that strategic objectives effectively connect to operational improvements and foster continuous improvement and strategic alignment. ~ Dr. Jimmy Gray

| Perspective | Objective | Measure | Target | Initiatives |

| Financial | Improve budget efficiency | Cost per transaction | Reduce by 10% in one year | Implement electronic document processing |

| Optimize resource allocation | Budget variance | Maintain within 2% | Conduct regular financial reviews and audits | |

| Increase revenue from services. | Revenue from premium services | Increase by 15% | Promote premium services like expedited processing and online services | |

| Customer | Enhance customer satisfaction | Customer satisfaction score | Achieve 90% satisfaction rate | Train staff in customer service best practices |

| Reduce wait times | Average wait time | Less than 15 minutes | Implement online appointment scheduling | |

| Improve service accessibility | Number of online services offered | Increase by 25% | Develop and launch new online services | |

| Internal Processes | Streamline service delivery | Processing time for applications | Reduce by 20% | Automate manual processes |

| Improve the accuracy of records | Error rate in processed documents | Less than 1% | Implement a double-check system and regular audits | |

| Enhance employee productivity | Transactions processed per employee | Increase by 10% | Provide training and upgrade technology | |

| Learning and Growth | Foster employee development | Employee training hours | 40 hours per employee per year | Offer regular training programs and workshops |

| Increase employee satisfaction | Employee satisfaction score | Achieve 85% satisfaction rate | Conduct employee surveys and improve the work environment | |

| Encourage innovation | Number of improvement suggestions | 5 suggestions per employee annually | Establish an innovation reward program |

This balanced scorecard helps the DMV align activities with its mission and strategy, improve internal and external communications, and monitor performance against strategic goals.

Another example is the U.S. Army Material Command’s Lean Six Sigma program, which led to $3.9 billion in financial benefits over five years. This example showcases the power of comprehensive performance metrics.

Engaging Stakeholders and Citizens

Stakeholder Management and Public Engagement

- Communicate improvements and benefits to the public.

- Engage citizens in process improvement initiatives.

- Ensure transparency in Lean Six Sigma efforts.

Performance Measurement and Tracking

- Establish key performance indicators (KPIs).

- Implement a system for tracking project benefits and ROI.

- Regular reporting and review of Lean Six Sigma initiatives

- Strategies for citizen engagement, including:

- Conducting surveys to identify priorities

- Involving citizens in improvement workshops

- Communicating improvement efforts and results

The City of Cape Coral, Florida’s utilities expansion program redesign exemplifies effective stakeholder engagement (Furterer, 2016).

Measuring ROI in Non-Profit and Government Settings

ROI demonstration involves the following:

- Quantifying financial and non-financial benefits

- Developing methodologies for calculating cost savings

- Using balanced scorecards for multidimensional tracking

A notable example of a government Lean Six Sigma project that demonstrates Return on Investment (ROI) calculation is the U.S. Army’s Red River Army Depot (RRAD) initiative. The Depot implemented Lean Six Sigma methodologies to improve operations, with a focus on the maintenance and refurbishment processes for military vehicles.

Project Overview:

- Objective: Enhance the efficiency of the maintenance and refurbishment processes to reduce cycle time and cost.

- Implementation: Applied Lean Six Sigma tools to identify and eliminate waste, streamline workflows, and optimize resource use.

ROI Calculation:

- Financial Gain:

- Reduced cycle time by 50%, leading to faster turnaround of vehicles

- Achieved cost savings of approximately $20 million annually due to increased efficiency and reduced labor costs

- Project Cost:

- Invested in Lean Six Sigma training for employees and process improvement initiatives, totaling around $2 million

- ROI:

-

- Calculated using the formula: ROI = ($20,000,000 – 2,000,000)/$2,000,000 x 100 = 900%

- Substituting the values: ($20,000,000 – 2,000,000)/$2,000,000 x 100 = 900%

This example illustrates how government agencies can apply Lean Six Sigma methodologies to achieve substantial improvements in operational efficiency, as well as significant financial returns on their investments.

Adapting Lean Six Sigma for Public Sector Challenges

Overcoming Resistance to Change

Common resistance factors include:

- Bureaucratic inertia

- Fear of job losses

- Skepticism about “business” methodologies in a government setting

The State of Iowa’s Lean Enterprise initiative successfully addressed resistance by emphasizing employee-driven improvements (State of Iowa, 2013).

Addressing Unique Government Constraints

Government agencies often face the following unique challenges:

- Complex regulatory requirements

- Political considerations and changes in administration

- Limited budget flexibility

The U.S. Air Force’s “Smart Operations for the 21st Century” (AFSO21) program successfully adapted Lean Six Sigma into the military context (Murman, 2012).

Adopting Lean Six Sigma Tools for Nonprofits

For non-profits, unique challenges may include the following:

- Defining “value” in terms of mission impact

- Focusing on donor satisfaction and retention

- Addressing volunteer management challenges

The American Red Cross’s reduction in its disaster response times demonstrates effective LSS non-profit application (American Red Cross, 2008).

Building a Culture of Continuous Improvement

Culture Change and Employee Engagement

- Develop a communication strategy to promote Lean Six Sigma.

- Encourage employee participation and idea generation.

- Recognize and reward successful projects and teams.

Continuous Improvement and Sustainability

- Regularly assess and refine the Lean Six Sigma program.

- Foster knowledge sharing and best-practice dissemination.

- Integrate Lean Six Sigma principles into daily operations. Key elements include:

- Leadership commitment

- Employee empowerment

- Integration of Lean Six Sigma principles into daily operations

The City of Denver’s Peak Academy exemplifies this installation of a continuous improvement culture in government (City of Denver, 2019).

Driving Operational Excellence in Government and Non-Profit

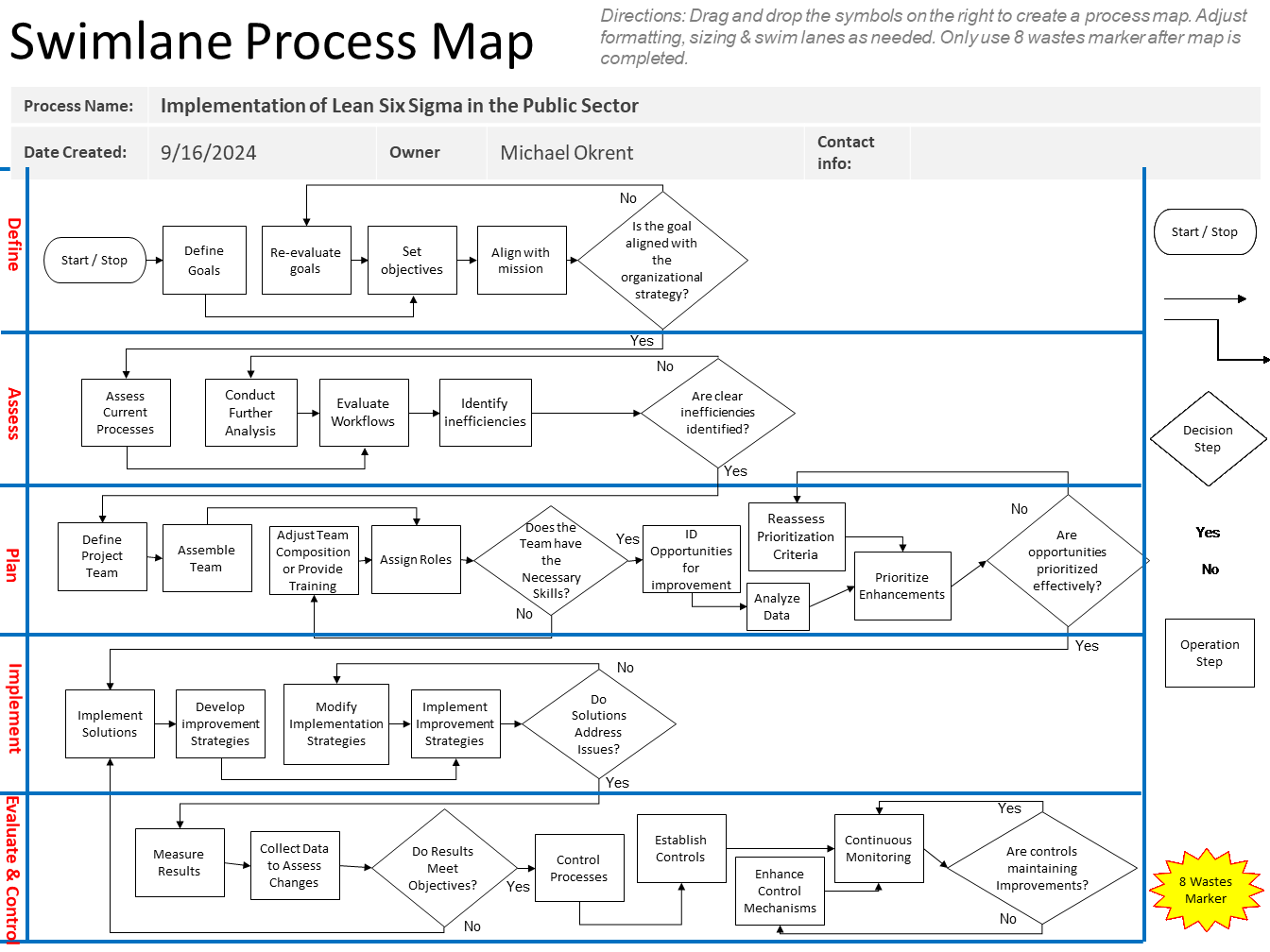

Developing a Lean Six Sigma Implementation Strategy

A comprehensive strategy includes the following elements:

- Current state assessment

- Goal setting and prioritization

- Deployment planning

- Establishment of governance structure

Lean Six Sigma Implementation Roadmap for the Public Sector

- Leadership Commitment and Vision

-

- Secure top-level management support

- Establish a clear vision for Lean Six Sigma implementation

- Align Lean Six Sigma goals with organizational objectives

- Assessment and Planning

-

- Conduct an organizational readiness assessment

- Identify key areas for improvement

- Develop a strategic implementation plan

- Build Infrastructure

-

- Create a Lean Six Sigma steering committee

- Establish a project management office (PMO)

- Define roles and responsibilities (Champions, Black Belts, Green Belts)

- Training and Skill Development

-

- Provide Lean Six Sigma training at various levels (Yellow, Green, Black Belt)

- Focus on public sector-specific case studies and examples

- Develop internal trainers for sustainability

- Pilot Projects

-

- Select high-impact, visible projects for initial implementation

- Ensure projects align with organizational goals

- Document and showcase early wins

- Scale Implementation

-

- Expand Lean Six Sigma across departments

- Integrate Lean Six Sigma into existing improvement initiatives

- Develop processes for project selection and prioritization

This roadmap addresses the unique challenges of the public sector, such as the need for transparency, stakeholder engagement, and alignment with public service goals. It emphasizes the importance of leadership commitment, cultural change, and sustainability. These elements are vital to successfully implementing Lean Six Sigma in government organizations.

With this roadmap, public sector organizations can systematically implement Lean Six Sigma. This implementation can lead to improved processes, enhanced service delivery, and better resource allocation.

The State of Connecticut’s Lean CT program provides a model for strategic implementation (State of Connecticut, 2016).

Training and Certification Programs for Public Sector Employees

Considerations for effective training:

- Adapting materials to public sector contexts

- Offering various certification levels

- Incorporating project-based learning

The U.S. Department of Defense’s robust training and certification process has been instrumental to its success (DoD, 2008).

Sustaining Improvements and Scaling Success

Strategies include:

- Regularly communicating results

- Integrating metrics into performance management

- Developing internal expertise

- Creating best practice sharing mechanisms

The Scottish Government’s Lean Six Sigma program demonstrates the successful scaling of its methodologies across departments (Scottish Government, 2015).

Emerging Trends and Future Directions

Lean Six Sigma methodologies and tools can be highly beneficial for government agencies, public sector organizations, and non-profits. LSS concepts relate to these sectors in the following ways:

Machine Learning Applications

In government and non-profit organizations, machine learning can assist in several areas:

- Improving Service Delivery: Predictive analytics help anticipate citizen needs and optimize resource allocation.

- Enhancing Decision Making: Data-driven insights can inform policy decisions and assess programs’ effectiveness.

- Fraud Detection: ML algorithms can identify fraud in public assistance programs or non-profit fundraising.

Robotics Process Automation (RPA)

RPA offers the following benefits in the public and non-profit sectors:

- Increased Efficiency: Automating repetitive tasks like data entry or report generation frees up staff for more valuable work.

- Cost Reduction: By streamlining processes, organizations can reduce operational costs and allocate more resources to their missions.

- Improved Accuracy: RPA can minimize human errors in tasks like benefit calculations or grant application processing.

Data Visualization and Business Intelligence

These tools benefit government and non-profit organizations in the following ways:

- Enhance Transparency: Visual representations of data can help communicate complex information to stakeholders and the public.

- Improve Program Evaluation: BI tools can provide insights into the effectiveness of public programs or non-profit initiatives.

- Facilitate Data-driven Decision Making: By making data more accessible and understandable, leaders can make more informed decisions.

AI-driven Simulation and Modeling

In the public and non-profit sectors, AI-driven simulations may have the following benefits:

- Optimized Resource Allocation: Simulations can help predict the impact of various resource allocation strategies.

- Improve Emergency Response: Modeling can aid in preparedness for natural disasters or public health crises.

- Enhance Policy Planning: Simulations can help policymakers understand the potential outcomes of various policy options.

Implementing AI Tools in Lean Six Sigma Projects

For government agencies and non-profits, integrating AI into Lean Six Sigma can assist in the following outcomes:

- Streamlined Operations: AI can help identify inefficiencies in service delivery or administrative processes.

- Enhanced Program Outcomes: Predictive modeling can help organizations focus on the interventions most likely to succeed.

- Improved Stakeholder Satisfaction: By reducing errors and improving efficiency, AI-enhanced Lean Six Sigma can lead to better experiences for citizens, donors, and beneficiaries.

These technologies and methodologies combined can enhance operational efficiency in government agencies, public sector organizations, and non-profits. They can help these organizations improve service delivery and ultimately and fulfill their missions to serve the public and/or beneficiaries. However, successful implementation requires careful planning, adequate training, and a culture that embraces both data-driven decision making and continuous improvement.

Integration with Digital Transformation

As governments continue to adopt digital technologies, Lean Six Sigma can be integrated with digital transformation efforts, and thus streamline processes and enhance delivery of services (Antony et al., 2020).

Application in Crisis Management

The COVID-19 pandemic highlighted the potential for Lean Six Sigma to improve government response to crises, from optimizing supply chains to streamlining emergency services (Hundal et al., 2021).

Focus on Citizen-centric Design

There’s a growing emphasis on Lean Six Sigma conjoined with design thinking to create more citizen-centric government services.

Seven Step Practical Implementation Guide

Step 1: Secure leadership commitment

Step 2: Assess current state and set goals

Step 3: Develop deployment plan

Step 4: Train employees and select initial projects

Step 5: Implement improvements and measure results

Step 6: Communicate successes and lessons learned

Step 7: Scale and sustain the initiative

Conclusion

Lean Six Sigma offers powerful tools for improving efficiency, enhancing transparency, and driving operational excellence in both government and nonprofit organizations. Though implementation in the public sector presents unique challenges, the potential benefits in terms of improved service delivery, cost savings, and increased citizen satisfaction are substantial.

As demonstrated by the numerous case studies and examples throughout this chapter, successful LSS implementation in government and non-profits requires strategic planning, leadership commitment, comprehensive training, and a focus on sustaining and scaling improvements over time. Lean Six Sigma principles can adapt the specific needs and constraints of government and nonprofit settings, and it aids these organizations in creating a culture of continuous improvement that will lead to lasting, positive change.

Looking into the future, the integration of Lean Six Sigma with digital advancements can assist with crisis management and facilitate citizen-centric design. These advancements present exciting opportunities for further enhancing public sector performance. Governments and nonprofits continue to face the pressure to do more with less, but Lean Six Sigma provides a structured approach to meet these challenges head-on. Ultimately, LSS leads to more effective and efficient public services that better serve citizens and communities.

References

- City of Denver. (2019). Peak Academy. https://www.denvergov.org/Government/Agencies-Departments-Offices/Agencies-Departments-Offices-Directory/Department-of-Finance/Our-Divisions/Budget-and-Management-Office/Denver-Peak/About

- Department of Defense. (2006). Continuous Process Improvement Transformation Guidebook. https://apps.dtic.mil/sti/citations/ADA485632

- Environmental Protection Agency. (2011). Lean in Government Starter Kit. https://nepis.epa.gov/

- Furterer, S. L. (2016). Lean Six Sigma in Service: Applications and case studies. CRC Press. https://www.routledge.com/Lean-Six-Sigma-in-Service-Applications-and-Case-Studies/Furterer/p/book/9781420078886

- George, M. L. (2003). Lean Six Sigma for Service: How to use Lean speed and Six Sigma quality to improve services and transactions. McGrawHill. https://www.academia.edu/12523016/Lean_Six_Sigma_for_Service_How_to_Use_Lean_Speed_and_Six_Sigma_Quality_to_Improve_Services_and_Transactions

- Maleyeff, J. (2007). Improving Service Delivery in Government with Lean Six Sigma. IBM Center for The Business of Government. https://www.businessofgovernment.org/sites/default/files/MaleyeffReport.pdf

- Mazzocato, P., Holden, R. J., Brommels, M., Aronsson, H., Bäckman, U., Elg, M., & Thor, J. (2012). How does Lean work in emergency care? A case study of a Lean inspired intervention at the Astrid Lindgren Children’s hospital, Stockholm, Sweden. BMC Health Services Research, 12, 28. https://doi.org/10.1186/147269631228

- Murman, E. M. (2012). Lean Enterprise Value: Insights from MIT’s Lean Aerospace Initiative. Palgrave Macmillan. https://link.springer.com/book/10.1057/9781403907509

- Rother, M. (1999). Learning to See: Value stream mapping to add value and eliminate Muda. Lean Enterprise Institute.

- State of Connecticut. (2016). CT Lean Home. https://portal.ct.gov/opm/fin-leanct/lean/leanct

- State of Iowa. (2013). Iowa Lean Home. https://dom.iowa.gov/state-government/lean-enterprise

- U.S. Army. (2010). Lean Six Sigma deployment report. https://www.army.mil/article/42784/lean_six_sigma_deployment_report

Chapter Summary