PART 2: METHODOLOGIES, PRINCIPLES AND TOOLS

5 Chapter 5: Kaizen Philosophy and Tools for Continuous Improvement

Introduction

Kaizen, a Japanese term meaning, “change for the better,” embodies a philosophy of continuous improvement. Within Lean Six Sigma, Kaizen plays a critical role in driving small, incremental changes that collectively lead to significant improvements in processes and organizational performance. This chapter delves into the Kaizen philosophy, its tools and techniques, and how to leverage it to achieve operational excellence.

Learning Objectives

- Describe the Kaizen philosophy and its role in Lean Six Sigma.

- Use Kaizen tools and techniques to take apart a problem or situation and think about it differently so that it helps people.

- Analyze how Kaizen can contribute to achieving operational excellence.

Learning Outcome:

To understand the methods of Kaizen to foster a culture of continuous improvement

The Kaizen Philosophy

The Kaizen philosophy emphasizes that small, continuous improvements can yield substantial results over time. It is rooted in the belief that everyone in an organization, from top management to frontline workers, should be involved in improvement activities. The core principles of Kaizen include:

- Incremental Improvement: Focusing on small, continuous changes rather than large, sporadic projects

- Employee Involvement: Engaging all employees in identifying and implementing improvements

- Focus on Processes: Concentrating on process improvements to enhance overall performance

- Simplicity and Cost-effectiveness: Implementing low-cost solutions that do not require significant investment

- Break down problems into discrete pieces.

- Study books on the natural world to understand how nature solved a specific problem, as nature bends, cuts, and uses its own techniques. Example: Velcro examined how burrs attach themselves to clothing.

In the context of Lean Six Sigma, the Kaizen philosophy complements the DMAIC (Define, Measure, Analyze, Improve, Control) methodology, as it provides a structured approach to identifying and implementing improvements.

Kaizen Tools and Techniques

Kaizen employs various tools and techniques to facilitate continuous improvement. These tools help to identify problems, analyze root causes, and implement effective solutions. Key Kaizen tools include:

- 5S (Sort, Set in order, Shine, Standardize, Sustain): This is a systematic approach to workplace organization that enhances efficiency and reduces waste (see Chapter 3).

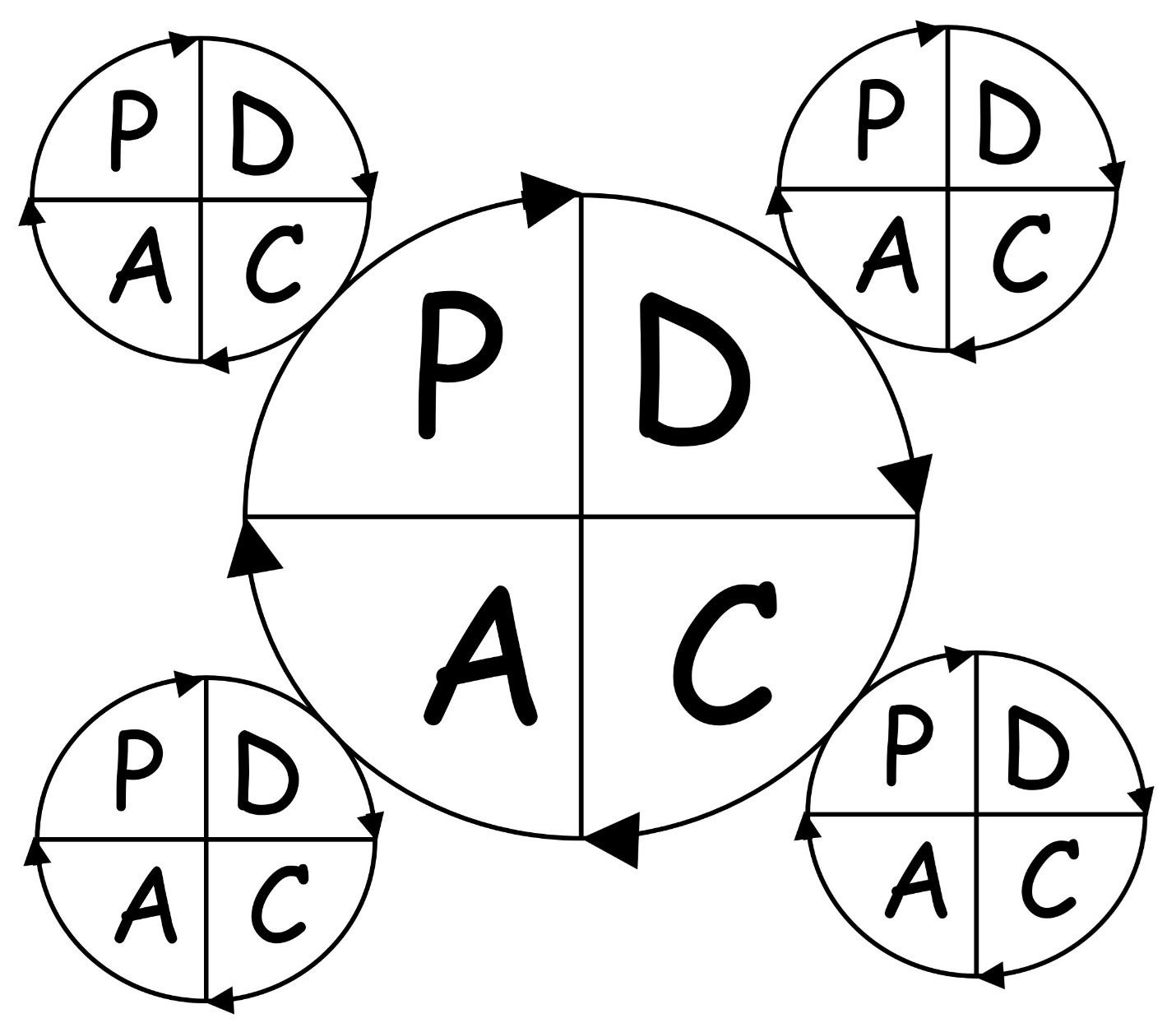

- PDCA (Plan, Do, Check, Act) Cycle: A four-step iterative process for continuous improvement.

-

- Plan: Identify an opportunity, and plan a change.

- Do: Implement the change on a small scale.

- Check: Use data to analyze the results of this change.

- Act: If successful, implement the change on a larger scale; if not, refine and test again.

The PDCA cycle, with PDCA for each letter. This illustrates improvement within the cycle itself. Although PDCA sounds linear, the process is iterative. You must evaluate, adjust, and improve in each phase.

In the video above[1], you will learn more about the PDCA/PDSA cycle (video length: 10:25).

- Value Stream Mapping: This is a visual tool to analyze the flow of materials and information required to bring a product or service to the customer. It identifies areas of waste (see Chapter 3).

- Gemba Walks: These are regular visits from managers to the workplace so they may observe processes and engage with employees to identify improvement opportunities. All Gemba walks should be done with a purpose, such as learning about the current state, confirming an improvement or a new standard in the work, or further understanding of an item on the value stream map.

In the video above[2], you will learn more about Gemba walks (Video Length: 5:49).

- Kaizen Events: These are focused, short-term working sessions to improve a specific process or area. These events bring together cross-functional teams to identify problems and root causes, propose solutions, and implement changes quickly.

In the above video[3], you will learn more about Kaizen Events (Video Length: 2:10).

- Root Cause Analysis (RCA and Five Whys): RCA is a technique used to identify the root causes of a problem by repeatedly asking “Why?” until the underlying issue is revealed. For example: Why are there chips in the oil? Where did they come from? The Whys can have more than one branch/reason. All of the branches in RCA should be explored to ensure that all potential reasons are identified. After determining the root causes, the next step is to obtain data as to how often they occur, the impact of their occurrence, and so on.

In the video above[4], you will learn more about the Five Whys approach to RCA (Video Length: 3:20).

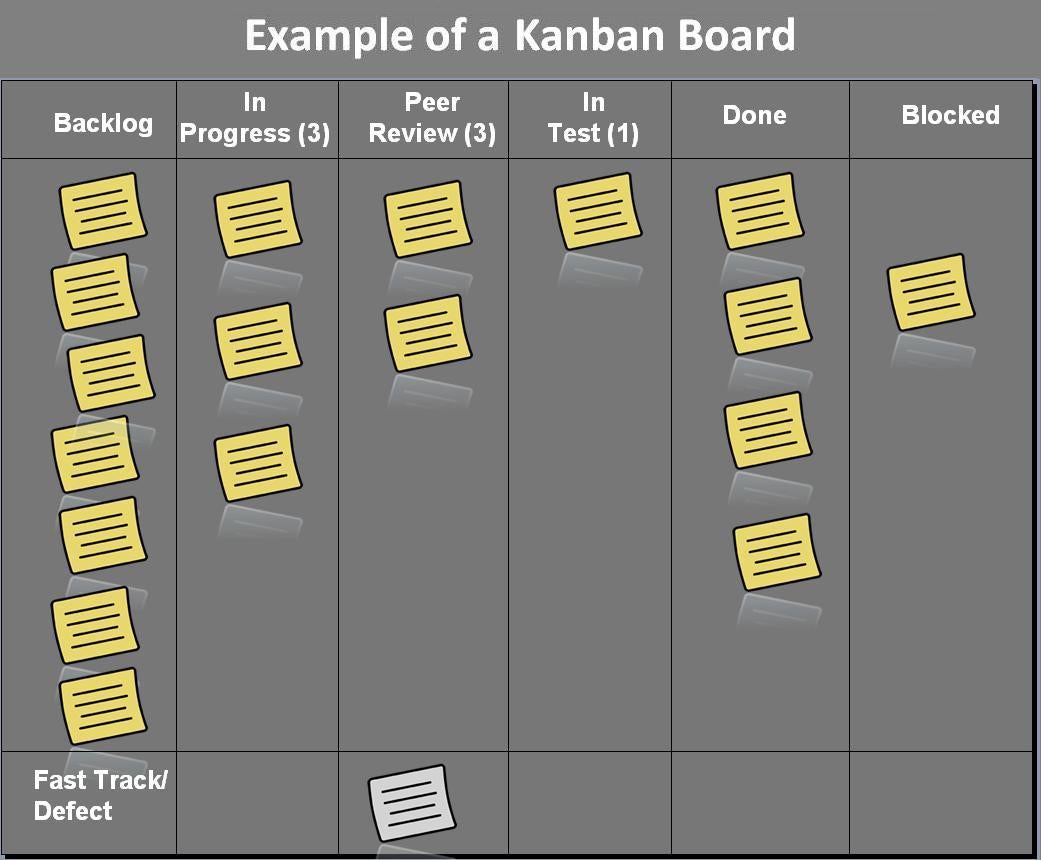

7. Kanban Board: Description and Example

Kanban Board Overview:

A Kanban Board is a tool used in project management to visualize work, limit work-in-progress, and maximize efficiency or flow. It originates from the Japanese term “Kanban,” meaning “signboard” or “billboard.” The Kanban Board helps teams visualize their workflow, improve their processes, and enhance productivity by making the status of tasks transparent to all team members.

Structure of a Kanban Board:

A typical Kanban Board consists of approximately four columns, each representing a different stage in the workflow. Common columns include:

- Backlog (To Do): Tasks that need to be done but have yet to be started

- In Progress: Tasks that are currently receiving attention and effort

- Review/Testing: Tasks that have been completed, but need to be reviewed or evaluated

- Done: Tasks that have been completed and reviewed

Additional columns may be added depending on the complexity of the workflow and the specific needs of the team.

Components of a Kanban Card:

Each task is represented by a Kanban Card, which typically contains the following information:

- Task title

- Description

- Task Owner(s)

- Key Date(s)

- Start date

- Due/target date

- Completion date

- Priority level

- Any relevant attachments or notes, such as progress updates, barriers, or needs

Example of a Kanban Board:

Imagine a software development team using a Kanban Board to manage their project. Below is an example of how it may appear.

Backlog (To Do):

- Task: Design login page UI

- Description: Create a wireframe and design for the user login page.

- Assignee: Jane Doe

- Due Date: June 25

- Priority: High

_______________________________________________________________________

Backlog (To Do):

- Task: Create database schema

- Description: Design and implement the database schema for user authentication.

- Assignee: John Smith

- Due Date: June 28

- Priority: Medium

__________________________________________________________________________

In Progress:

- Task: Develop login API

- Description: Implement the backend API for user login functionality.

- Assignee: Alice Johnson

- Due Date: June 22

- Priority: High

__________________________________________________________________________

In Progress:

- Task: Set up CI/CD pipeline

- Description: Configure continuous integration and continuous deployment pipeline.

- Assignee: Bob Lee

- Due Date: June 24

- Priority: Medium

__________________________________________________________________________

Review/Testing:

- Task: Write unit tests for login API

- Description: Create and run unit tests for the login API to ensure functionality.

- Assignee: Alice Johnson

- Due Date: June 23

- Priority: High

__________________________________________________________________________

Done:

- Task: Install and configure project dependencies

- Description: Set up the development environment with necessary project dependencies.

- Assignee: Jane Doe

- Completed Date: June 20

__________________________________________________________________________

Benefits of using a Kanban Board:

- Visualization: Team members can see the status of each task at a glance, which enhances transparency and accountability.

- Work-in-progress (WIP) Limits: To prevent bottlenecks caused by overcommitting or overwhelming the team, WIP limits can be set for each column. For example, the “In Progress” column might have a WIP limit of three tasks to ensure that the team doesn’t take on too much at once.

- Flow Management: By tracking the movement of tasks from one column to another, teams can quickly identify barriers, inefficiencies, and areas for improvement.

- Continuous Improvement and Staff Engagement: Regular reviews using huddles around the Kanban Board help teams reflect on their processes and make necessary adjustments to improve efficiency and productivity.

Kanban/Kaizen Simulator

Try out this simulation of a Kanban Board.

https://businessmap.io/simulation

Kanban Board:

Example Scenario:

A software development team might use the above Kanban Board to visually track progress. Below are definitions for each column.

Tasks:

- Backlog (To Do):

Design login page UI: Jane Doe is assigned to create wireframes and design the user login page. The task is due on June 25 and is marked as a high priority.

Create database schema: John Smith is assigned to design and implement the database schema for user authentication. The task is due on June 28 and is marked as medium priority.

- In Progress (limit 3 cards):

Develop login API: Alice Johnson is implementing the backend API for user login functionality. The task is due on June 22 and is marked as a high priority.

Set up CI/CD pipeline: Bob Lee is configuring the continuous integration and continuous deployment pipeline. The task is due on June 24 and is marked as medium priority.

- Review/Testing:

Write unit tests for login API: Alice Johnson is creating and running unit tests for the login API to ensure it functions correctly. The task is due on June 23 and is marked as a high priority.

- Done:

Install and configure project dependencies: Jane Doe has completed setting up the development environment with the necessary project dependencies. This task was completed on June 20.

Using this Kanban Board, the team can easily track the progress of each task to ensure that work is evenly distributed and to identify any potential bottlenecks or delays in the project. By limiting the number of tasks in the “In Progress” column, the team can focus on completing current tasks before taking on new ones, thereby maintaining a steady workflow and achieving continuous improvement.

Steps to Determining Kanban Board Capacity

Determining the capacity of any phase of a Kanban Board involves understanding and setting WIP limits for each phase or column. These WIP limits ensure that the team does not take on more work than they can manage at any given time, which in turn helps to identify bottlenecks and optimize flow through the process. Below is a step-by-step guide on how to determine the capacity of any phase of a Kanban Board:

- Understand the Workflow:

Map out the entire workflow from start to end. Identify each phase of the process (e.g., Backlog, In Progress, Review/Testing, Done).

- Assess Team Capacity:

Evaluate the team’s overall capacity. Consider factors such as the number of team members, their skills, and the amount of time they can dedicate to the tasks. Involve the team in setting and adjusting WIP limits. Their firsthand experience and insights can help to determine realistic and effective limits.

- Historical Data Analysis:

Look at historical data to understand how much work has typically been completed in each phase over a given period. This can provide insights into the team’s natural capacity for each phase.

- Set Initial WIP Limits:

Based on the workflow, historical data, and team capacity, set initial WIP limits for each phase. A common starting point is to set the WIP limit to be slightly less than the number of team members who work on tasks in that phase.

- Monitor/Confirm and Adjust:

Continuously monitor the flow of tasks through each phase. Use metrics such as , , and to assess whether WIP limits are effective.

Adjust WIP limits as necessary. If tasks consistently get stuck in a phase, this may indicate that the WIP limit is too high. Conversely, if tasks are flowing through too quickly, this may indicate that the WIP limit may be increased.

- Use Feedback Loops:

Implement regular feedback loops, such as daily stand-ups (huddles) and retrospectives, to discuss the effectiveness of current WIP limits and make necessary adjustments.

Monitoring Metrics:

: Available time/Customer demand = time required to balance flow (see Appendix for details).

Cycle Time: The time from the beginning of one item to the beginning of the next item (this could apply to parts or surgeries)

Lead Time: The time between an item’s request and its delivery to the customer

Throughput: The number of tasks completed in a given period

These metrics can help to understand whether WIP limits are set appropriately and where adjustments may be needed.

For example, if cycle time is 2x Takt time, the WIP limit is probably too high. You should then reduce the WIP so that tasks can move more quickly through the production process.

Conclusion:

Determining the capacity of any phase of a Kaizen Board is an iterative process. It involves setting initial WIP limits based on team capacity and historical data, monitoring task flow, and making necessary adjustments according to feedback and observation. By continuously refining WIP limits, teams can optimize their workflow, reduce bottlenecks, and enhance overall productivity.

Kaizen versus Kanban Boards

Purpose:

A Kaizen Board is a type of Kanban Board used to manage and visualize continuous improvement activities within an organization. Its focus is identifying, tracking, and implementing improvements to processes, systems, or products.

Kanban creates an improvement mindset which then improves flow. Kanban helps to manage flow and make it visible and physical.

Kaizen Board Structure:

The Kaizen Board structure typically includes sections for capturing improvement ideas, tracking their implementation, and monitoring the results.

Common columns may include the following:

- Ideas/Opportunities: A place for team members to submit suggestions for improvements

- To Do: Approved improvement activities that are ready to be enacted

- In Progress: Improvement activities currently in process

- Completed: Implemented improvements

Results: Tracking the outcomes or impacts of the improvements

Benefits of using a Kaizen Board:

- Emphasizes employee involvement and engagement in suggesting and implementing improvements

- Encourages a culture of continuous improvement by making it easy for all team members to contribute ideas

- Useful in Kaizen events or workshops in which teams focus on specific improvement projects

Example:

A Kaizen Board in a manufacturing plant might track suggestions for improving machine efficiency. Employees submit ideas, such as modifying a tool or changing a workflow. Once an idea is approved, it moves through the board from “To Do” to “In Progress” and then to “Completed.” In “Results,” the idea’s impact on efficiency is measured.

| Kanban Board | Kaizen Board | |

| Focus | Managing and visualizing the flow of work through distinct stages of a process | Monitoring continuous improvement initiatives and tracking the implementation of improvement ideas |

| Usage | Day-to-day management of workflow, emphasizing ongoing task and process management | Organizing and tracking improvement activities, often involving periodic Kaizen events or workshops |

| Structure | Typically includes columns representing distinct stages of a workflow, such as backlog, in progress, review/testing, and done | Typically includes columns for ideas, to-do items, in-progress improvements, completed improvements, and results |

| Objectives | Aims to optimize workflow, manage WIP, and ensure efficient task completion | Aims to engage employees in suggesting and implementing incremental improvements |

Conclusion

While both Kanban and Kaizen Boards are essential tools in the Lean and Agile methodologies, they serve different purposes. The Kaizen Board is centered on fostering a culture of continuous improvement. This occurs by capturing and implementing ideas for improvement. In contrast, the Kanban Board is focused on managing and visualizing the workflow of tasks, and it optimizes efficiency and productivity. These tools are complementary, and they can be used together to enhance overall organizational performance.

Fostering a Culture of Continuous Improvement

To successfully implement Kaizen and achieve continuous improvement, organizations must cultivate a culture that supports continuous improvement efforts. This includes:

- Leadership Commitment: Leaders must demonstrate a commitment to continuous improvement through their actions and decisions. This includes providing necessary resources and recognizing employee contributions.

- Employee Empowerment: Employees should be encouraged and empowered to identify improvement opportunities and take initiative. This can occur through training, open communication, and creating an environment where experimentation is valued.

- Collaboration and Teamwork: Cross-functional collaboration is essential. It serves to identify comprehensive solutions and ensure that improvements benefit the entire organization.

- Recognition and Reward: Recognizing and rewarding employees for their contributions to continuous improvement spurs motivation and reinforces the importance of Kaizen.

Achieving Operational Excellence through Kaizen

Operational excellence is the ability of an organization to consistently meet or exceed performance goals in a manner that is sustainable over time. Kaizen contributes to operational excellence in the following ways:

- Reducing Waste: Continuous improvement efforts help to identify and eliminate waste, leading to more efficient processes and reduced costs.

- Improving Quality: With its focus on process improvements and root cause analysis, Kaizen helps to reduce defects and enhance product or service quality.

- Enhancing Customer Satisfaction: Improved efficiency and quality result in better products and services, and this leads to higher customer satisfaction and loyalty.

- Increasing Flexibility: A culture of continuous improvement enables organizations to respond quickly to changes in the market or customer needs. This enhances their agility and competitiveness.

- Sustaining Improvements: The principles and practices of Kaizen ensure that improvements are sustained over time, contributing to long-term operational excellence.

Case Study: Kaizen in Action

To illustrate the impact of Kaizen, consider the example of the Toyota Motor Corporation. Toyota has long been a proponent of the Kaizen philosophy. With its continuous improvement initiatives, Toyota has achieved remarkable efficiency and quality in its manufacturing processes. Regular Kaizen events and Gemba walks are integral to Toyota’s approach. They enable the company to identify issues and implement improvements quickly. Kaizen has been a key factor in Toyota’s reputation for reliability and operational excellence.

Conclusion

The Kaizen philosophy, with its focus on incremental improvements and employee involvement, is a powerful tool for fostering a company culture of continuous improvement. By using Kaizen tools and techniques, organizations can achieve significant increases in efficiency, quality, and customer satisfaction. In the context of Lean Six Sigma, Kaizen plays a vital role in driving operational excellence and ensuring sustainable success.

Chapter Summary

This chapter provides a comprehensive exploration of the Kaizen philosophy and its application within Lean Six Sigma. It equips the reader with knowledge in how to foster a culture of continuous improvement and achieve operational excellence.

References

- Imai, M. (1986). Kaizen: the key to Japan’s competitive success. McGraw-Hill.

- Liker, J. K. (2004). The Toyota Way: 14 management principles from the world’s greatest manufacturer. McGraw-Hill.

- Ohno, T. (1988). Toyota Production System: beyond large-scale production. Productivity Press.

Kaizen Board References

Below are some sources that provide more detailed information on determining the capacity of a Kaizen Board and related Kanban concepts.

- Anderson, D. J. (2010). Kanban: Successful Evolutionary Change for Your Technology Business. Blue Hole Press. This book introduces Kanban in the context of the technology business and provides foundational principles for implementing Kanban, including setting WIP limits.

- Scrum.org. (n.d.). Kanban Guide. https://www.scrum.org/resources/kanban-guide-scrum- teams). An overview of Kanban structure and use in Agile project management.

- Atlassian. (n.d.). Kaizen Board: What it is and how to use it. https://www.atlassian.com/agile/kanban/boards. This article provides a comprehensive introduction to Kanban Boards, including tips for setting WIP limits and managing workflow.

- Businessmap, (n.d.). Description-of-the-Kanban-Board (Includes videos)(https://knowledgebase.businessmap.io/hc/en-us/articles/360027116291-Description-of-the-Kanban-Board). An in-depth look at the basics of Kaizen Boards and practical advice for implementing them in various contexts.

- Agile Alliance. (n.d.). Kaizen Board. (https://www.agilealliance.org/glossary/kanban-board/). A glossary entry that provides a concise explanation of Kaizen boards and their role in Agile project management.

These references will provide you with a deeper understanding of Kaizen boards, how to set WIP limits, and how to determine the capacity of the distinct phases in your workflow.

Appendix

What is Takt Time?

Takt time is a critical concept in Lean manufacturing. It measures the rate at which a product or service must be produced in order to meet customer demand. It is essentially the heartbeat of the production process, ensuring that products are manufactured at a pace that aligns with customer needs.

The Formula for Takt Time

The formula to calculate takt time is straightforward:

T = Ta /D

Where T = Takt time, Ta = available production time (net time available for work, excluding breaks, maintenance, and other non-production activities), and D = Customer demand (the number of units required during the specified period).

Example Calculation

To illustrate, consider a manufacturing line with the following parameters:

Available Production Time (Ta) = 8 hours per day minus 30 minutes for lunch, 30 minutes for breaks, 10 minutes for a team briefing, and 10 minutes for maintenance checks.

Gross time: 8 hours = 480 minutes

Deductions: 30 minutes (lunch) + 30 minutes (breaks) + 10 minutes (briefing) + 10 minutes (maintenance) = 80 minutes

Net available time = 480 minutes 80 minutes = 400 minutes per day Customer Demand (D) = 400 units per day

Using the formula:

T = 400 minutes/400 units = 1 minute per unit

This means the production line must produce one unit every minute to meet the customer demand.

Benefits and Uses

Takt time is beneficial for the following reasons:

- Aligns Production with Demand: Ensures that production rates match customer demand, preventing overproduction and underproduction

- Reduces Waste: Helps in eliminating non-value-added activities and optimizing the production process

- Improves Efficiency: Enhances productivity by standardizing tasks and reducing variability in the workflow

- Enhances Customer Satisfaction: By ensuring the timely delivery of products, Takt time helps to maintain a high level of customer satisfaction.

Real-world Example

In a 3D-printing machinery manufacturing company, if the average customer demand is 10 machines per week and the available production time is 2,250 minutes per week (after accounting for breaks and other non-production activities), the Takt time would be:

T = 2,250 minutes/10 units = 225 minutes per unit

This means the production team needs to complete one 3D printing machine every 225 minutes (approximately 3 hours and 45 minutes) to meet the customer demand.

By using Takt time, operations managers can optimize production processes, ensure efficient use of resources, and maintain a continuous flow of work to align with customer needs.

- Video Source: YouTube.com 1, “Plan, Do, Study, Act Cycle: PDSA” by The Improvement Academy, https://youtu.be/_YOq4KXBahM?si=RdJwthOqzkgL8J5v (Accessed December 11, 2024) ↵

- Video Source: YouTube.com, “7 Steps to performing effective Gemba Walks” by Rever, https://youtu.be/QaqNqgPiFIE?si=Ys3MYmuvssnAUlKy (Accessed December 12, 2024). (5:49) ↵

- Video Source: YouTube.com, “What is a Kaizen Event? Your Roadmap Rapid Improvement.” by KaiNexus, https://youtu.be/aEO6T2uNsaE?si=Jw1JNzKgZWRtPnsF (Accessed December 12, 2024). (2:10) ↵

- Video Source: YouTube.com, “Clarifying the '5 Whys' Problem-Solving Method” by Lean Enterprise Institute, https://youtu.be/SrlYkx41wEE?si=Uu1FcQOAXqk7oURv (Accessed December 12, 2024). (3:20) ↵

Time to complete one unit of work from start to finish.

Example: In a coffee shop, cycle time is measured from order placement to drink delivery.

Total time from order to delivery.

Example: Time between ordering a pizza and it arrives at your house.

Amount produced in given time.

Example: Number of homework problems completed per hour.

Production pace needed to meet customer demand.

Example: If a factory operates 8 hours and customers demand 480 units daily, takt time is 1 minute per unit.