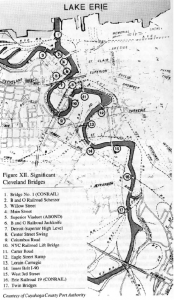

Four major high-level bridges with fixed spans now cross the lower Cuyahoga River in the heart of the city. As they transport stone and iron ore to the upriver mills, lake vessels (even with masts of 98 feet) affect only the low-level bridges.

The oldest high-level bridge in daily use is the Detroit-Superior Bridge, opened in 1918. It-together with the Lorain-Carnegie Bridge (1932), the Main Avenue Bridge (1939), and the Inner Belt Bridge (1959)-carries the heavy traffic of the major arterials from the downtown section of Cleveland to the West Side.

The Old Superior Bridge

But what about the seven, semi-circular stone arches standing west of the river? The approach is at West 25th Street and Detroit Avenue, but the arches end abruptly with a barricade at the river. These arches are all that remain of the original Superior Viaduct, predecessor of the Detroit-Superior Bridge. As a bridge, the old structure had a short but useful life of some 43 years-from the opening day, 28 December 1878, to the day of its successor opened in 1918.

Let us digress and discuss this original Superior Bridge, which was to be the catalyst, joining the East and West Sides.

Even before the Civil War the need for a high-level bridge to facilitate traffic to and fro across the river was recognized. In fact, Oliver P. Baldwin, editor of the Cleveland Daily Advertiser, advocated the erection of just such a bridge as early as 1835, In his editorial he wrote:

On visiting Cleveland and Brooklyn a few days since, and surveying the disadvantages which exist in communication between those two cites, I was naturally led to reflect what great plan could be adopted which the prospects of the place and the condition of the country would warrant to remove all those difficulties…

That some communication between these two rival cities of tenfold greater magnitude and convenience than any or all that had been enjoyed, is absolutely necessary, needs no proof.

The following project is therefore laid before your readers and the whole community. It is to be built by a company chartered for the purpose, or by the State, a grand and stupendous bridge from the top of the hill in Cleveland to the top of the hill in Ohio City, from suitable points in each place, and that it be built of stone with a sufficient number of arches of the best mason work, supported by stone piers laid deep and strong, either solid or arched widthways, and that this bridge be 120 feet wide, all of the best stone work, and level on the top for the above railroads, and a common road with side-walks and iron railings, and that walls of brick or stone be carried up on each side of the bridge with a center or partition wall in the middle, and other partitions walls the other way as necessary. And that floors be placed in all these apartments as many stores as the whole height of the bridge would allow, and that rooms on each side, sixty feet deep, and such width as would be convenient, would form the best, most convenient and permanent stores and warehouses that could be conceived of…

The upper stories might be occupied as shops, offices, or even boarding houses, and every apartment accessible by flights of stairs as well as from the top of the bridge as from the ground. This bridge would be high enough to allow any masts or rigging of any vessel that sails the lake to go under, so that it would not impede the navigation of the river, and that these stores, warehouses, rooms and tenements, would rent for a sum sufficient, with what two railroad companies can well afford to pay, to refund the whole expense of the work in ten years from its completion…[1]

It took thirty-five years for such a vision to take shape. In 1870 there were several low-level bridge crossings, all with movable spans to permit the flow of traffic: Main Street, Center Street, Columbus Street, and Seneca Street (West Third). The population of Cleveland was about one hundred thousand, and the city was rapidly growing in industries as well as in population. In April 1870, East Siders were invited to attend a lecture by J.F. Holloway at the East Side High School building, which stood at Euclid Avenue and East Ninth Street. Holloway presented a plan for a high bridge, including an estimated cost and survey figures of traffic crossing the Cuyahoga River at different points.

A year later the city Fathers decided that, without some supporting state legislation, the city was powerless to undertake the project. R.B.

Dennis, a member of the Ohio House of Representatives, introduced a bill authorizing building the bridge. The bill passed the House but failed in the Senate.

The opponents of the bridge found an ally in the Cleveland Herald, whereas the advocates had the support of the Leader. The Herald declared the project impossible, warning that it would saddle Clevelanders with a debt of two million dollars. The reply to this in the Leader read:” The old lady shakes her withered finger solemnly protesting against building the waterworks, the railroad, and the swing bridges. During the same year, an editorial appeared in the Ashtabula Sentinel, which left no doubt as to what the newspaper thought of the whole idea:[2]

Our exchanges are discussing a scheme that has been proposed by some hair(air) brained mechanic of building a bridge across the valley of the Cuyahoga upon a level nearly level. The poor fellow who proposed it talks as if it were really a sane project, the Leader supports it as if it were possible, and the Herald opposes it-as it anybody outside of a madhouse intended to build and use such a bridge. Why not start a bridge. Why not start a question of tunneling the lake to Canada?.”[3]

On 18 April 1871, a resolution was introduced in the City Council providing for the formulation of a committee to determine the best site for a bridge and to formulate plans for improving communication between the residents of the West Side and the East. After long discussion the Council adopted the resolution on 8 May 1871. Also, the U.S. Corps of Engineers agreed to such a bridge with a swing-span for navigation purposes. During the summer of 1871 surveys were made to determine the route of the bridge. One plan was to connect Ohio Street (now Central Avenue) on the east with Lorain Street on the West. At a meeting of City Council on 18 April 1871, a petition was presented which asked that the necessary “surveys, plans and estimates be made for a high-level bridge” having a double-track carriage-way and providing for streetcar tracks and sidewalks. This petition was signed by F.W. Pelton, and sixty-seven others. One of Cleveland’s notable citizens and an advocate of the bridge in City Council was John Huntington, who introduced the resolution of construction of the viaduct and who was later a member of the committee that supervised construction.

It is to be noted that the least preferred of these suggested routes was the one that years later was adopted for the Lorain-Carnegie Bridge, a structure that has never carried its predicted traffic volume, nor has its lower level, designed for streetcars, ever been used except for utility ducts.

At a public meeting held on the West Side on 22 April 1871, it was argued that the number of people crossing the viaduct each day would be 15,240 and the number of teams of horses 4,671. Consequently, a two-cent toll would be exacted from pedestrians, streetcars, and vehicles which would ultimately pay the cost of construction and would create a sinking fund, so that the bridge would cost the city nothing. At this same meeting a resolution passed approving the bill introduced in the Legislature by Mr. Dennis, and its immediate passage was urged. In January f 1872 the legislature passed this bill, thus granting permission to build the viaduct. This action was bitterly assailed by the Cleveland Herald.

On 30 January 1872, a resolution was introduced in City Council proposing that railroad tracks be laid to the site of the bridge to facilitate movement of materials. This action necessitated a change in the bill, so that a new one had to be written and approved. A bill was also introduced to vacate a part of the Ohio Canal in the designated area. Both of these measures were strenuously opposed by East Siders. But Judge Coffinberry argued in favor of the bridge, by pointing out that the city was growing rapidly and that the existing bridges would soon be wholly inadequate. He recalled the time when the Lighthouse Bridge (Main Street) was built only after long litigation and after predictions of bankruptcy, of ruinous conditions, and of dangers to navigation.

On 27 April 1872, a new bill authorizing Cleveland to occupy a part of the Ohio Canal site was adopted. The question whether tolls should be collected on the new bridge was left open in the bill; permission was given to let the voters decide.

Meanwhile two new routes had been surveyed: one from the intersection of Superior Avenue and Water Street (West 9th Street) to the intersection of Pearl (West 25th Street) and Franklin; the other from the intersection of Superior and Union Lane (West 10th Street) to the intersection of Pearl and Detroit. The second route was the one recommended to Council and finally approved.

In April of 1872 the proposal for the new bridge was submitted to the vote of the people. The result was 7,548 in favor of the bridge and 2,623 against. The first estimated cost was fixed at $759,328.78.

A protest against construction was filed on 18 January 1873-a protest signed by Charles A. Otis, H. Garettson, W. P. Southworth, Fayette Brown, D.P. Eeles, Samuel Williamson and 252 more. These were influential men in the city. They claimed that the cost was excessive and that a bridge could be built for much less. A similar complaint was filed on 11 February. Although these petitions were referred to the Board of Improvements, they had no effect.

On 19 August, an ordinance authorizing the issue of bonds to the amount of $117,893 for acquiring land came before the Council was defeated by a vote of eleven to twelve. The next morning the Leader declared, “Thus the ordinance was consigned to its fate and the viaduct killed.”[4]

However, public agitation was aroused. Citizens on the West Side held an indignation meeting, the result of which was a petition sent to the Council to reconsider, signed by four thousand voters. Despite constant opposition, land was finally purchased; and on 7 October 1873, E.W. Ensign was awarded a contract for the masonry construction, his bid of $512,720 being the lowest. Mr. Ensign was a Berea, Ohio quarry owner and contractor; among other large contracts of his was the construction of the Lake Shore R.R. in 1871-2; the culverts of which are built of Berea sandstone which was famous at this time. Sherman and Flager constructed the masonry piers.

Even after the work had begun and $500,000 expended, resolutions were submitted to the Council demanding that the project be abandoned. From 1870 to its completion in 1878, agitation for and against the bridge continued. Strong opposition came from the East Side, whose residents would claimed that taxes would be excessive. West Siders protested that the bridge would deflect trade to the East Side. Injunctions and objections created frequent changes in plans. Initial plans had called for a roadway 50 feet wide, but in 16 March 1875, a change was made to adopt a 64-foot roadway. One argument advanced for the widening was that business houses could be built on each side of the stone arches. The total cost with these changes was approximately $2,200,000, the cost of the bridge structure being $1,600,000. To meet the increased cost resulting from the change of plans, the question of voting additional bonds was submitted to the voters on 4 May 1876. That the viaduct now had firm friends was indicate by the fact that 6,863 voted in favor of the bond issue, while only 3,181 opposed it.

On 21 December 1875, the City Council asked the Legislature to authorize the collection of tolls not to exceed three cents for a single team and five cents for a double team each way. This money was to defray the expense presented, asking the legislature to permit toll to be collected “from each passenger and vehicle passing over the bridge, as it may be deemed necessary.”[5]

At a council meeting held on 18 April 1876, Horatio C. Ford introduced the following resolution:

That as a measure of equalization and the relief from immediate burdensome taxation, it is the judgment of the council that for the first twenty years after the completion of the Superior Street Viaduct, a toll shall be required from all traffic passing over the structure..[6]

Then on 5 December 1876, N.A. Gilbert introduced a resolution calling the attention to the council to the action of the legislature authorizing the city to collect tolls. But in spite of various reminders and ordinances, and in spite of its reassurances to persuade voters that taxes would not be raised, at no time was toll of any kind taken for using the viaduct.

Work on the bridge began in March of 1875, with the driving of the piles. When borings were taken, it was discovered that timber piles had to be driven to refusal (that is, 20 feet deep) into clay substratum, and it took a great many piles, because they had to be placed under the whole width, which was 80 feet. If all the piles had been laid end to end, they would have extended for forty miles; upon the piles timber and concrete grillages were erected, which bore, in turn, the masonry work of the piers.

On 20 May 1875, the first blocks for the semi-circular masonry arches were laid. Starting from the western approach there were eight masonry arches of 83-foot span and two arches of 971/2 foot span, with retaining walls. This masonry work was 1,382 feet in length and 72 feet in height above the pile foundations. More than two million cubic feet of sandstone was quarried, cut and shipped from Berea, Ohio.

Then came a pivot swing-span, 332 feet long. The eastern approach consisted of a continuous plate-girder bridge of three 162-foot spans, followed by two 145-foot spans, and one 160-foot span. Total length of the viaduct was 3,211 feet, and it rose 86 feet above the river. The wide side-walks and double tracks of streetcars encouraged use by pedestrians and passengers alike. Claflin and Sheldon constructed the iron spans and the swing span. Lauderback and Company built the iron railing.

Mayor P. Payne, in his annual message to the City Council delivered 11 April 1876, reported:

The Superior Street Viaduct, the foundations for which are being laid, has been urged forward with commendable energy, and the quality of the work is above criticism. In March, one year ago, the City Council, on recommendation of the Board of Improvements, determined to widen the structure fourteen feet, both to increase its strength and enlarge its usefulness. This the present administration recognized as a measure of wisdom, as the immense weight of the superstructure, considering the character of the rock beneath it, required great strength to ensure its durability: and there would be no justification for the expenditure of so much money unless when built it afforded abundant facilities for transit across the valley for many years to come. On the original plan it would not accommodate two railroad tracks and two roadways; this width seemed indispensable. To avoid litigation and liability to pay damages for obstructing Superior Street, and to the effect a better crossing of the River, the Board of Improvements in June last recommended that the route of the easterly side of the river be changed by deflecting sufficiently to the south to take it out of Superior Street. The Board also recommended that the easterly terminus be extended to Water Street (West 9th Street), and that the superstructure be raised in the center sixteen feet. The City Council, with but two or three dissenting voices, concurred in these recommendations. The object in raising it which these changes were made indicate their expediency, although attended with considerable expense. The engineer’s estimate of extra cost for widening both sides is $203,000; for raising, $260,000; total $463,000.

Mayor Payne was concerned over the increasing cost of the bridge and expressed his concern in guarded words:

A provision in the supplementary viaduct law recently enacted by the general assembly of the State, required the council of cities acting under it, within two years, after its passage, to create a sinking fund for the extinguishment at maturity of all indebtedness incurred by its authority and that of the act to which it is supplementary. This law provides also that the proceeds of the sale or lease of all lands or interest in lands acquired by virtue of the same authority, shall be appropriated to the exclusive use of this fund. On the 25th of October last (1875) the mayor executed on behalf of the city, by authority of the council, a contract with the Valley Railway Company to lease to said company for a term of ninety-nine years, the strip of land known as the canal bed, in which the city’s title will be complete as soon as the new lock into the rivers is finished, which will probably be in July next. The consideration to the city, which will be paid on the execution of the lease, is $265,000 in first mortgage gold bearing bonds of the company. I therefore recommend that immediately upon the receipt of these securities a sinking fund be established for the exclusive purpose of redeeming the viaduct and canal bonds, and that these and other assets and money’s designated in this law be applied to this use. One other suggestion respecting sinking funds. We have levied annually for the past ten years an average of two mills for sinking fund purposes, and we have had an average surplus to the credit of this fund or more than one thousand dollars. This surplus has been constantly invaded, without authority of law, to meet deficits in the funds of other departments, and has thus encouraged extravagance, or has laid in the treasury idle. I recommend that at the earliest possible time it be placed where its earnings will meet some of our increasing obligations. No resource the city has is too small to be husbanded and made available to aid the taxpayers in times like these..”[7]

Mayor Payne’s words went for naught and his advice unheeded. While the $265,000 in gilt-edged certificates were delivered, the 71/2 percent annual interest payments were received but once, for the Valley Railroad went bankrupt the next year. The Cleveland and Valley Railroad took over the lease, but made no payments to the city.

In a report upon the bridge, written in 1909 by the City Engineer B.F. Morse, the foundations for the stone work was described. Mr. Morse, a direct descendant of Samuel B. Morse, the inventor of the telegraph, was City Engineer from 1875 to 1884. Had it been possible. Mr. Morse wrote, to have built these piers upon a rock foundation, they would have lasted several hundred years; but that was impossible. When the arches were being completed, all of the abutments and piers settled from two inches to four or five inches. However, after the viaduct was opened, very slight additional settlement occurred.

A few years after completion, the city attempted to open the river channel west of the center pier of the iron drawspan, as had been originally intended, but when pier eight settled several inches, work on the channel opening was stopped. After that, no further settlement took place. In the 1909 report, Mr. Morse wrote that all the arches showed cracks running lengthwise near the centers of the arches, cracks varying from 1/2 to 1/4 inches at the crown of the arches, and diminishing towards the spring line. Caused by the settling of the pile foundation, these cracks did not affect the safety of the viaduct, declared Mr. Morse. Every so often, some latter-day dooms-dayer finds these old cracks and expresses the same concern all over again.

The fixed spans east of the river and the draw (except the 145-foot continuous plate girders) were of the type then called the Linville double-intersection type of truss. J.F. Linville, a distinguished American engineer, was Chief Engineer of the Pennsylvania Railroad. His wrought-iron truss was a trapezoidal one, with double intersecting diagonals-that is, the diagonals were a forty-five degree angle; but the panels were on half as long as they were deep.

All parts were proportioned to carry a live load of one hundred pounds per square foot of roadway, or 6,400 pounds per linear foot bridge, with a safety factor of five (then considered abundantly strong for city bridges).

The drawspan, with a pivot in the middle, has a total length of 322 feet, each arm being 166 feet in length from the center. Contraction during cold weather left an opening at the ends of the draw of from 2 to 3 inches; and, of course, in warm weather expansion closed the space. The rapid movement of streetcars on and off the span, the often bad condition of the rails and frogs and of the wedges under the ends of the draw-all caused extraordinary strain on the span and led to delays in opening and closing. The span was, however, constructed with extra weight because there could be no protective piling under the ends when the span was open. In 1909 the span was opened on an average of 3,600 times a year, or 300 times a month. When in good working order, it took four to six minutes to open or close.

When finally completed, the viaduct cost $1,574,921.32, exclusive of right-of-way, which cost in excess of $600,000. In its day it was acclaimed an architectural wonder. On 27 December 1878, it was opened to traffic. The booming of cannons awakened the citizenry at dawn. The bridge was decorated with thousands of flags. In mid-morning the two promoters of the structure, Henry Wood and Beldon Seymour, standing at opposite ends of the viaduct, began a slow march toward the middle of the bridge, where they met and shook hands. Then a federal salute was fired, bands played, crowds shouted. A big parade, which took 20 minutes to pass a given point, formed. In it were the Cleveland Grays, the Light Artillery, the Fire Department, the Hibernian Guards. In the line were Governor R.M. Bishop of Ohio, Governor M. Mathews of Virginia, and mayors galore.

The celebration continued throughout the afternoon in the old Tabernacle at the corner of Ontario and St.Clair Streets, where the Mayor, William Gray Rose, the two governors and others gave speeches. William McKinley was invited to attend, but did not.

The banquet at the Weddell House that evening was the most elegant social event yet seen in Cleveland. There were ten courses, with food and liquor piled high on tables. On the menu were boned jellied turkey, gelatin of chicken, larded quail, larded prairie chicken, saddle of venison, partridge, lobster, egg kiss pyramids, Geneva cake, orange mange, sliced oranges in cherry wine, slice pineapple in champagne, Bavarian cream, chantilla cream, etc. There were fifteen speakers and many toasts.

And the Hon, R.C. Parsons philosophized in the customary rhetorical vein:

Who and where are the men who erected the magnificent ruins on the banks of the Nile, whose colossal monuments of engineering skill and power lie scattered along its shores? Where are the men who built the aqueducts of Rome?…as it has been with other nations, so it is likely to be with us. The time may come when in some far-off century the orator or the poet of a yet unborn race will point to the remains of the splendid works of engineering skill scattered all over the American continent, and among them the Cleveland viaduct whose successful completion we this day commemorate, as marks of high civilization and intelligent skill of a simple remembered people..[8]

However, the disadvantage of the central drawspan to allow for passage of high masts and funnels caused continuous irritation and finally led to the replacement of the bridge. Condemned in 1920, its demise took place in 1922, when a crowd of people witnessed the demolition of the river span, destroyed by 150 pounds of dynamite. Recently one of the local newspapers consigned the remaining stone arches to the wreckers ball with the words, “a bridge to nowhere awaiting its doom.” These are words that are typical to the unimaginative.

Today, “Ohio City” is being restored by owners of buildings and residences in the Franklin Circle area. Bridge and Jay Avenues are beginning to recapture the charm of the gay nineties and earlier. And, although the old “Angle” district and the high-rise structures along West 25th are not available as renting units except to the poor and elderly, why not provide for more apartments with a view of the river? What would be more appropriate than a pair of high-rise structures on both sides of the Superior Viaduct, straddling Elm and Riverfront Streets, that would have made-to-order private road and courtyard with a view that is unsurpassed? [Figure IV.]

The legal and economical problems of most civic projects are serious stumbling blocks, but women are persistent. The Viaduct View Inc., headed by Isabel Tener, includes two service club-Soroptimst International of Cleveland and Altrusa International of Cleveland. Mrs. Tener was not the first to formulate plans for the use of the old arches but she was the first to do something tangible. The aim of the Viaduct View is to restore, maintain and beautify the old viaduct. Already $93,000 of the projected $2509,000 has been raised. With the backing of many of Cleveland’s prestigious groups, the project stands a good chance of being realized.

Somebody always is suspect of an old bridge put to new use; modern stress analysis do not know how to figure the loads in a stone arch. The design loads used one hundred years ago are different from those used at present. But as people plaza (perhaps with shops) and a service road, the old bridge needs only a new railing, some cleanup work and drainage to start on a second century of service.

The Detroit-Superior High Level Bridge (1918)

Only a few years after the opening of the “Old” Superior Viaduct, people began to clamor for a true “high level” bridge, for, as traffic increased, the delay caused by the opening and closing of the drawspan proved to be a source of irritation. At the time of construction there had been some talk of raising the level of the structure in order to dispense with the drawspan, but most people seemed to have agreed with the city councilman who remarked, “What would be the use? You might better go down a hill on terra firma as up a hill on a bridge in the air.”[9]

On 15 February 1909, R.F. Morse, the City Engineer, made a plea for incorporating the stone arches of the old viaduct; if a high level bridge is to be built, why not use as much of the old structure and right-of-way as possible? It would be a pity to take down those grand old stone arches that with a good foundation would last hundreds of years.” [10]

Although we can sympathize with him, when even today we admire the strength of the remains of these still beautiful arches, his plea was in vain. The good citizens of Cleveland wanted a new and spectacular bridge-one as great as any in the world. Compared to the opposition that dogged the erection of the old bridge, this new bridge was relatively easily achieved. As Stanley L. McMichael wrote, in 1918:

The new Detroit-Superior High-Level Viaduct…stands as a splendid monument to the enterprise and aggressive action to the citizens of Cuyahoga County. Nowhere in America does there exist at the present day any bridge or viaduct that can rival in artistic design, usefulness, and permanency of construction this massive span which binds together the two most populous sections of the metropolis of the middle west.. [11]

The general route chosen, one that has been used for a century and a quarter, crosses the river near the present low-level Center Street span, where the first floating bridge had been built.

After considerable discussion and many meetings with representatives of the U.S. Corps of Engineers, of the shipping interests, and of the city and County, it was at length agreed that a vertical clearance of 93 feet was sufficient for the new bridge.

The bridge was funded by the Cuyahoga County Commissioners, since both Superior and Detroit Avenues are county thoroughfares.

However, the City of Cleveland cooperated, by paying for the removal of underground pipe and wire obstructions, and by re-routing street-car lines. Actual cost, including the land purchased for right-of-way, was $5,407,000 (about twice the cost of the old bridge): $1,687,200 for land and $3,719,800 for the superstructure.

The bridge is 3,112 feet long and originally had a pavement width of 75 feet. (It has, however, been widened recently). There are twelve concrete arches, varying in size from 58 feet to 174 feet, and an overhead steel-arch span, which crosses the river on a skew with a minimum clearance for lake vessels of 96 feet. The steel span is 591 feet and the maximum height, at the crown, is 196 feet [Figure V].

A lower deck provided for six streetcar tracks. Original plans did not include the construction of subway entrances, but after work had begun, it was determined that subways would greatly aid in eliminating traffic congestion at the approaches. Provision was made to construct a four-track

subway, entering the lower level at West 6th Street, and two double-track sub-track subways at the western end, one rising to the surface on West 25th Street near Church Avenue and the other emerging on Detroit Avenue near West 29th Street. The ramp portions have since been filled in after streetcars were eliminated from city streets.

The foundations were carefully laid, perhaps because memory of foundation troubles of the old bridge still lingered. The foundations of the new bridge rest partly on clay and partly on concrete piles. The west abutments and piers 5 to 11 inclusive, rest on precast reinforced concrete piles varying in length from 25 to 50 feet. They were required under tests to carry a load of 60 tons for seven days, with a maximum allowed settlement of 1/4 of an inch. The use of precast reinforced concrete piles were relatively new type of foundation. Piers 1 and 2 were carried down 35 to 40 feet into a natural substratum of clay, bringing the footings of the piers 60 to 65 below the surface grade of the ground. They are of the caisson type, built in cribs, of reinforced concrete.

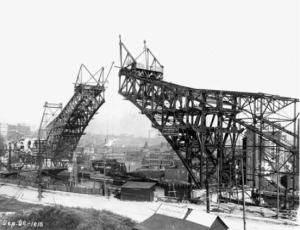

The superstructure east of the river was erected with the aid of a double cableway having a span between towers of 1200 feet. The steel head tower was 180 feet high and the main cables 21/2 inches in diameter. The cableway had and ordinary carrying capacity of 8 tons, but it handled 121/2 tons in emergencies. A complete saw-mill plant and framing yard were maintained to build forms, and material was carried by the cableways.

The twelve concrete arches are, with the exception of the first one at the east end, of the same general type. They consist of four ribs, each reinforced at points where possible tension may occur. The arch spanning the tracks of the Big For and Erie Railways had to be different because the required clearance did not permit the use of arch centering. Accordingly, three-hinged steel arches of a greater rise, the lower deck being carried through, were used to support the weight of the concrete while it was poured around the steel arches.

The outstanding feature of the bridge is the steel trussed arch. It is a three-hinged 591-foot arch, designed to carry a load of 10,000 pounds per linear foot of bridge, plus impact varying for different positions. The span trusses are of nickel steel; other parts are of carbon steel. The arch has a rise of 144 feet, a depth at the crown of 20 feet, and at the end of the hangars of 91 feet.

The arch was erected by cantilever method, anchored with back stays to the main concrete piers. The construction of each arm started from 90-foot steel towers which, erected just back of the abutment piers, sustained the traveler and its two stiff-legged derricks.

The engineers had computed that, when the trusses were finally placed and before being lowered to take bearing on the center pin, the bearing faces would be about twenty inches apart. When the last section in the trusses had been placed, the two halves lined up within one-eighth of an inch, a difference easily adjusted by means of a cable. The halves were within twenty inches of bearing when lowering operations began. Final adjustment varied only two inches from the computations. On the morning of 8 October 1918, nearly a foot of sky showed between the arms, During the afternoon the toggle screws which supported the two halves were released and the bridge-ends settled together. “She fits like paper on the wall”, shouted the steel boss and hurried to his office for a box of cigars. The structural iron worker cheered and went to a nearby saloon to drink a toast to the foreman; steamboats and factories in the Flats blew their whistles. But this was the only celebration; no formal ceremonies were held, for 1918 was a war year, with little incentive for merrymaking.

The total weight of steel in the central span is 8,500,000 pounds. There were 195,000 pounds of rivets used in the field joints, and 45,000 pounds of paint was required to cover the arch.

Following the completion of the reinforced concrete arches of the approaches and of the main central arch, earth fills were made between walls at each end of the bridge; decks were waterproofed and pavements laid [Figure VI].

In 1918 the bridge was the largest double-deck, reinforce concrete structure in the world. Although the structure no doubt appeared more light and diaphanous than it does to us today, it is still a handsome bridge. One of the officials suggested that it be called the “rainbow bridge”, and, although the title never caught on, it does reflect the point-of-view of the people of Cleveland toward the new wonder. We may find the concrete arches a bit too massive; however, they were remarkable in their day because they do not in any way suggest stonework-they speak the new language of reinforced concrete with relatively thin ribs and open spandrel design. The through steel arch of the central span gives the whole structure a dramatic focal point, and the slaying of the chords at the spring line creates a spacious and stable effect. A famous bridge engineer of the early twentieth century, Henry Grattan Tyrrell, greatly admired this bridge, and, in an article he wrote in 1918 on Cleveland bridges, he compared it favorably with the Pia Maria Bridge over the Douro At Oporto, Spain, and with the Garabit Viaduct in France (both of which had been built by Gustave Eiffel)..”[12]

The county engineers responsible for the project were A.B. Lea, Frank R. Lander, and the Chief County Engineer, W.A. Stinchcomb. Their assistants were A.M. Felgate and A.W. Zesiger. City Engineer Robert Hoffman had charge of the removal of pipe and wire obstructions, and of the supervision of local traffic, A number of contractors were involved: The O’Rourke Engineering Company of New York built the two main river piers; the Great Lakes Dredge and Dock Company place the foundations for the piers of the concrete arches; the Hunkin-Conkey Construction Company had the main contract for the concrete superstructure; the King Bridge Company built the great steel central span; Bates and Rogers of Chicago were in charge of the subway approaches; the Trinidad Paving Company laid the pavements; the Ohio Cut Stone Company furnished the limestone balustrades.[13]

The Detroit-Superior High-level Bridge has just undergone extensive repairs and remodeling. Albert S. Porter, County Engineer (at the time of this writing), employed Howard, Needles, Tammen and Bergendoff to investigate the structure and report on its state. Because of age and corrosion caused by air pollution, the bridge had deteriorated to the point where structural adequacy of some of its members was questionable. In addition to the aging process there were two basic causes for deterioration: (1) certain instances of faulty initial construction, and (2) failure of the drainage system to function properly, which resulted in extensive salt damage.

Two types of steel had been used in the original construction. The main truss members and hangars are of corrosion-resisting nickel steel; the floor system and bracing members are of ordinary carbon steel. The nickel steel floor systems showed signs of corrosion. The consultants designed means to improve and widen the bridge.

During 1967 and 1968, the deck was repaired and was made into a six-lane roadway, to accommodate increased traffic loads, by cantilevering the extra lanes outside the center span.[14]

The Lorain-Carnegie Bridge (1932)

South of the Detroit-Superior High-Level Viaduct stands the second major bridge across the Cuyahoga Valley-the Lorain-Carnegie. Completed in November of 1932, it was declared by the American Institute of Steel Construction to be one of the most beautiful bridges built in that year.

As early as 1916 (that is, before the Detroit-Superior High-Level Bridge was finished) agitation grew for a third viaduct to cross the valley. Bond issues were passed, but World War I shelved all such plans.

Then during the twenties the Van Sweringens, in the fullness of their power, had built the terminal complex at the foot of Huron Road and also their Shaker Square development with the Rapid Transit. These terminals suggested that Carnegie Avenue could become a major thoroughfare, with traffic moving from the Heights to Public Square. Likewise, from the West Side, Lorain Avenue would carry heavy traffic to downtown Cleveland. In 1924 a City Planning Commission report recommended that the bridge be built immediately.

In 1927 a Citizens Committee of fifteen was appointed to make recommendations to the County Commissioners regarding the construction of the Lorain-Carnegie Bridge. The recommendations this group made were twofold — one set applying to the bridge proper and another applying to the approaches. The fact that many of these latter recommendations were never carried out is perhaps one reason why the bridge has failed to serve the city as extensively as had been predicted. Since the construction of the Inner Belt Bridge (I-90) and the Main Avenue Bridge, through traffic has completely neglected this bridge, and pedestrian traffic is non-existent.

In 1927 The Clevelander published an article concerning the November election, in which the voters had approved two bridge bonds (one for the structure and one for the land). At that time the Chamber of Commerce specified that pier placement should not interfere with any future river straightening; and the City Plan Committee was concerned with traffic and transportation distribution. The writer of the article in The Clevelander had some interesting ideas:

But while these are in process of reconcilement the committee on city plan is to take just as firm a stand on the entirely indisputable economic fact that an ugly Lorain-Central Bridge would by distinct economical handicap to the Cuyahoga Valley. Steel and concrete, as materials which can achieve beauty in building, have certainly demonstrated themselves to Clevelanders in the Telephone Building and in the Union Terminal Tower. That steel alone can be arched into bridges of beauty has been proven in the United States and in Europe. Wilbur J. Watson, internationally known bridge engineer and chairman of the City Plan Committee’s subcommittee on bridges, in his recent volume, “Bridge Architecture”, cited many such instances.

The first question in the taxpayer is supposed to ask is whether it is good business to spend his money to obtain — not only the certainty that the bridge won’t fall down and will carry loads, but also noble proportions and details in such a strictly utilitarian structure. According to most of the cities in the United States which have built such structures in recent years, the answer is undoubtedly — yes. Pleasing lines do not need to be expensive.

It is not a question of cost, so much as of skill, on the part of the designer to design to this goal. It is becoming usual to have important bridges designed by engineers in collaboration with an architectural firm…as a structure that satisfies esthetic taste pays not only in increased values of surrounding property, but in the civic imponderables -civic pride and civic pleasure..”[15]

To make a justification for a steel bridge as late as 1927 seems strange to us, but Clevelanders were conservative; they associated beauty with stone or concrete arches, and probably the public had to be educated.

In 1930 work began. The bed of the Cuyahoga Valley is composed of glacial deposits of silt, sand, and clay overlying the native shale to a depth of approximately 150 feet. The characteristics of this overburden vary greatly but in general cannot be relied upon to carry heavy loads. Therefore, all of the piers are founded upon piling, concrete piles being used under all piers except those at the crossing of the river, which are founded upon timber piling. The footings for the river piers were carried down to an average depth of 38 feet below the river level.

The superstructure consists of fourteen cantilever-truss spans, varying in length from the largest, 299 feet — which is over the river — to 132 feet at the ends. Total length is 5,865 feet; and it elevation of 93 feet is that demanded by the Corps of Engineers for shipping clearance. It was not generally known that there are two decks; the upper one has a 60-foot road-way and two 7-foot walks; the lower deck, which has never been used, was designed to accommodate two rapid transit tracks and two 18-foot trucking roadways.

The bottom chord of the trusses was curved for esthetic reasons. It was found that the increased cost of curving these chords was slight and was fully warranted by the better appearance, since the side elevation of this bridge is seen from the other viaducts and from many of the principal office buildings overlooking the valley. For similar reasons a concrete facia was carried from the tops of the concrete piers to the underside of the coping; and the parapets, too, add greatly to the bridge’s beauty, for the top and bottom rails and the posts are of Berea sandstone with inset panels of cast pierced aluminum.[16] Albert Porter insisted that the high-strength superstructure was necessary because of the extra weight added by the sandstone. The ornamental railings and sidewalks that contribute greatly to the massive appearance of the structure are expensive to maintain and will probably be removed when the bridge is rehabilitated.

But the most obvious architectural treatment is the presence of four colossal pylons, on each of which are two sculptured stylized figures that symbolize progress in transportation. These were designed by Frank Walker of the architectural firm of Walker and Weeks, and executed by Henry Hering, New York sculptor, who also designed the statues, symbolizing

Security and Integrity, in front of the Federal Reserve Bank Building. The huge figures on the pylons hold in their hands a hay rake, a covered wagon, a stage coach, a passenger automobile, and four types of trucks. A sandblasting would reveal the designer’s original concept [Figure VII].

Silicon steel was used for the main members of the trusses, and haydite concrete for the 8-inch deck slab. The 3-inch wearing surface of asphalt was laid directly upon the roadway slab. About 71,000 yards of concrete were used and 13,000 tons of structural steel. Total cost, excluding that of real estate and property damage, was about four million dollars.

The bridge was built by the Cuyahoga County engineers under the direction of Fred R. Williams County Engineer, and A.M. Felgate, County Bridge Engineer. The design was by Wilbur J. Watson, Consulting Engineer, with F.R. Walker, architect — two eminent names in Cleveland.

The completion of this bridge was marked by fitting festivities. On the evening of 9 November 1932, several thousand persons, according to the newspapers, “braved wintry winds to attend the formal opening, at the west approach.” Besides the formal ceremony, festivities included a masquerade, dancing, and the distribution of more than one hundred prizes donated by the owners of stands in the West Side Market. County Engineer, John O. McWilliams, and a candidate for municipal judge, made a brief appearance and delivered a short address. Speaking of the west approach he said:

This improvement was partly due to the efforts of the county engineer’s office…and I hope someday the same sort of improvements can be carried further over Lorain Avenue.

Some of the stores were set back from the property line, but the street was never widened.

Although he did not win a prize for the most original costume, the most uncomfortable masked person was an unidentified young man attire (or rather more unattired) as a cannibal. According to the news reporter, this young man’s knees could be seen knocking together by those in the farthest rows from the platform.[17]

The eminent minister of Pilgrim Congregational Church, the Reverend Dan F. Bradley, preached a sermon upon the opening of this bridge, using it as a symbol of brotherhood and unity.

The bridge is essential to the highway. Without it the best of roads fails of its purpose. Fort the river divides men and the bridge brings them together.

Pilgrim Congregational Church at West 14th Street and Starkweather Avenue was the most prominent of the churches on the West Side, having many influential families on its membership rolls. In this same sermon Dr. Bradley spoke of the symbolism of the bridge:

Now, the metropolitan city, after many years of earnest effort by the citizens of the West Side, has erected a noble bridge, the Lorain-Carnegie, best of all of our bridges…

The bridge is a thing of intimate human interest. Its spaciousness is a guarantee of safety for untold precious lives…and the bridge is a symbol of a moral quality without which the edifice would be impossible. The bridge is built with truth, in obedience of physical and chemical laws which are the laws of God, Thieves, murderers, and liars cannot make good bridges. There must be honesty, from the blueprints of the architect to the mixture that goes into the cement hopper.

The bridge is a significant emblem, pointing to the aspiration of a community like ours to attain the best and high achievements for the common welfare. The bridge belongs to every citizen; to the rich man and to the very poor man. It marks the cooperation of us all to reach perfection.

We have a great and increasingly important city, and a people who can build and pay for so great an enterprise are not cheap and inferior people; and you and I who are a part of the great metropolis must live up to all that is great and fine in our community. We must use the bridge to inspire our children to live worthily and nobly as befitting people who have such wonderful advantages..”[18]

Perhaps the first conclusion to this account of the building of the building of the Lorain-Carnegie Bridge is to put out that the builders of Cleveland were striving to design and create beautiful structures to serve the community and to improve the environment. The bridge is a monument to that effect. It has recently been placed on the National Register of Historic Monuments [Figure VIII].

The bridge was closed on October 1, 1980 for three years, for major repairs and renovation. Chemical and waste discharge from industry in the Flats has caused pollution and erosion of the concrete.

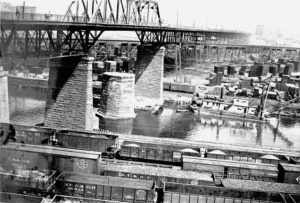

The Main Avenue Viaduct (1939)

The first Main Avenue Bridge was built in 1869, a swing structure, one of the first iron bridges in the city. Cleveland’s first three log huts stood only three hundred feet from its site. It was, of course, a “low-level” structure, with a 200-foot swing span that was pivoted on a central pier; width was 31 feet. The Herald wrote of this new marvel, “so perfect is the mechanism…a boy of 12 years can swing the mighty mass with ease.” [19] In 1885 the bridge was rebuilt and operated by steam; but in 1915 the bridge was moved slightly and repaired; and longer approaches were constructed to permit larger vessels to enter. Records of 1943 show that the draw was swinging 9000 times a year. The new high-level Main Avenue Bridge replaced this swing bridge, which was torn down in 1947. Nevertheless, it had had a long and useful life. It was an extremely popular bridge for the Westsider who used Bulkley Boulevard to get downtown, for the Detroit-Superior Bridge had bottlenecks at both ends because of the streetcar subways.

As early as 1930 plans for a Main Avenue Viaduct were drawn up, and in November of that year a $6,000,000 bond issue for the bridge was passed by the voters. No doubt the Great Depression postponed further work, But, with the formation of the Public Works Administration, the county commissioners recognized a new source of revenue, so that the bridge was built with the aid of the PWA.

Numerous and complex are the problems that must be solved in the building of a great bride, even before construction begins. Right-of-Way and land must be purchased, making sure that legal and ethical obligations have been met. The fundamental problem facing the engineers is to gain agreement from all agencies and organizations involved: agreement on the location, type of structure, cost estimates and finances, accessibility of the bridge. As plans for each unit — the piers, abutments, spans, and so forth — are formulated, they are submitted to the County Commissioners for approval, to the city council, to the City Planning Commission, and to the County Planning Commission. The State Highway Director investigates all plans as a precaution; district U.S. Army engineer must give his permission; finally, the Public Works Administration must affix its stamp of approval upon every sheet. Literally hundreds of sheets, blueprints, plans, and specifications are required to be so endorsed.

Ground was finally broken on 12 May 1938. The bridge, 2,250 feet long, stretches across a half-mile; the total length is 5,920 feet, but, including approach ramps, it is 8,000 feet. Beginning at the western end of the bridge proper, near West 25th Street, there are five steel spans each 200 feet long. These are followed by two spans of 240 feet each, and a span of 320 feet, which is 150 feet west of West 10th Street. All spans are of the truss-cantilever types. Construction was begun at both ends. Clearance for river traffic is 98 feet, except for the central span, which is 115 feet above the water. The roadway is 82 feet wide. The principal part of the east ramp, across the railroad tracks, consists of a four-span continuous structure supported on three parallel plate girders of unusual depth and length. The supports are skewed so that no two girders are alike. Professor William J. Eney of Lehigh University was engaged to build models for this testing. .”[20] These girders are 270.8 long, the longest girder-spans built in America up to that time.

The concrete piers of the river span are anchored in hard blue clay, 45 feet below the riverbed, and stand nearly 100 feet back from the river bank, to permit river widening without interfering with the bridge.

As the steelwork of the superstructure was built out from both ends, the moment of the meeting was the most spectacular. An amusing column about this appeared in the Cleveland News, written by Howard Beaufait:

I joined the rubberneck gang of sidewalk experts supervising construction of the new Main Avenue Bridge…

Trying to appear as nonchalant as possible. I leaned against a building down in the Flats. Next to me stood a man in a leather zipper jacket. His eyes were sad and contemplative, and his eyebrows were arched in such a way the he look perpetually amazed.

“How in the hell are they going to make that thing meet in the middle?” he asked. …I didn’t know, I said, but I understood it was a ticklish job to get that final connecting link into place…

My companion made a clucking noise with his tongue. He said it was a mistake, that they should start on one end and just keep on going until they reached the other end….”[21]

At any rate, we know that the meeting was achieved; on 25 April 1939, in the presence of a large crowd, a golden rivet was driven home to link the east and west sides [Figure IX].

In a record-breaking time of less than a year and a half, this bridge was completed and opened with a befitting celebration. Total cost of the bridge was $7,500,000. On 6 October 1939, more than a thousand people attended the dedication; workmen, military organizations, and fraternal bodies participated in a parade. The city, county, and nation were represented on the speaker’s program; and after the ribbon had been cut, there was dancing on the bridge.

In charge of construction was John O. McWilliams, County Engineer. His associates were W.E. Blaser, F.L. Plummer, R.W. Dietrich, and C.M. Haake, Wilbur J. Watson was the consulting engineer. County Commissioners were Joseph F. Gorman, John F. Curry, and James Reynolds.

From its opening, this bridge has carried increasingly heavy traffic, inasmuch as it is, in effect, the bypass around the city for through traffic and links the Lakeland Freeway with Bulkley Boulevard.

Although the bridge is barren of any ornamentation and is functional in design, the American Institute of Steel Construction awarded it an Honorable Mention for its appearance. This is no doubt because of the clean lines and although the bridge was built as a cantilever, the bottom members form a curve that gives the pleasing appearance of an arch.

Only the street lighting was a failure. The public objected to the starkness of the yellow sodium vapor lights used first in Cleveland and promoted by a prominent lighting firm. The effect of temperature on the operation of these bulbs had not been sufficiently studied. This problem solved, the outdoor mercury vapor lights are now widely used, and the very latest ones — the “warm golden light” flooding the Public Square and Euclid Avenue — are a direct descendant of those once used on the bridge. The structure was extensively repaired in 1978.

The Old Central Viaduct

The Inner Belt Bridge (Interstate 90) stands approximately where Cleveland’s second oldest viaduct — the Central Viaduct — once crossed the valleys of Walworth Run and the Cuyahoga River. As it was with the old Detroit-Superior Bridge, the Central Viaduct was debated pro and con for a decade before it was built, for the project met with vigorous opposition. Pressure urging construction of the bridge was brought to bear upon City Council by the South Side as early as March 1879, when Councilman James M. Curtiss introduced a resolution asking that the City Engineer report upon the best location for such a structure. But nothing was done until 1883, at which time the resolution was passed, and the council authorized an expenditure of a million dollars. In December 1885 the ordinance of construction was approved, bids were opened by November of 1886, and in May of 1887 ground was broken.

Its location was chosen to bring traffic from the southwest parts of the city to the downtown area. At its south end was a neighborhood which had long been called University Heights. (The present suburb of University Heights is a latter-day copy). A college had been started but lasted only a year; however, the existing street names in the area are reminders — such as Professor, Literary and College. The neighborhood was fashionable because it supposedly provided escape from malaria and from the chills and fever which were believed to have been caused by the marshy lowlands of Cleveland.

The contract provided for two bridges. The main structure known as the Central Viaduct, was 2,839 feet in length and extended from genteel Jennings Avenue (West 14th Street) to Central Avenue (Carnegie) on the East Side. The second bridge connected Abbey Avenue to Lorain Avenue at West 25th Street. The so-called Walworth Run section of 1,088 feet, which can be best be seen from Scranton Road, is still in daily use..”[22] it is 70 feet wide and 76.5 feet above Scranton Road. Its iron and steel spans are supported by iron towers resting on masonry foundations. Its concrete mesh deck installed in 1930 belies the age of the underlying structure. The City Engineer’s report of 1914 indicated that the “iron” had a tensile strength of 50,000 pounds per square inch, which may account for the long life.” [23] The engineer in charge of the steel work was Frank Osborn (the founder of the Osborn Engineering Company). Both branches were constructed by the King Iron Bridge and Manufacturing Company.

The piers of the Central Viaduct were a masonry; the spans of the superstructure were steel trusses. Known as the “stilt” type, the bridge consisted of a serious of braced towers and deck spans of varying lengths. Originally it had a swing section over the river to permit the passing of high-masted ships. This was removed in 1912 after a streetcar accident. The bridge was then converted to a true high level by replacing the draw with an overhead truss. The roadway was 101 feet above the river, with a 40-foot vehicle lane and two sidewalks of eight feet each. Its costs was $675,000. The City Engineer’s office furnished the design and construction specifications, with C.G. Force in charge in the beginning, followed by Walter W. Rice; W.W. Hughes was consultant in the design [Figure X].

Three years after approval of the ordinance of construction the bridge was opened on II December 1888. The steel trusses were draped with multicolored bunting and garlands of flowers. A parade of soldiers and civilians formed at 1 p.m. on Superior Avenue at Public Square, moved west across the old Superior Viaduct, then south along Pearl Street (West 25th Street) to Lorain; then it turned left across the New Abbey Street Bridge over Walworth Run to the western approach of the new bridge. There the procession stopped for the dedication. Zenas King, who started manufacturing Cleveland bridges in 1833, and took out one of the earliest patents on swing bridges, spoke for the King Iron Bridge Manufacturing Company. The first iron arch and swing bridges in northern Ohio were manufactured by this firm, founded in 1858. In 1871 the King Iron Bridge and Manufacturing Company was organized by Zenas King, Thomas A. Reeve, A.B. Stone,

Charles E. Barnard, Charles Crumb, Dan P. Eells, and Harry Chisholm. Under Harry King, the founder’s son, the firm furnished structural and wrought iron work for most major building projects. In 1876 annual sales reached nearly a million. A nation-wide business developed. By 1886 bridges built by the firm, if placed end-to-end, would have extended more than 150 miles.[24] And in 1893 the plant, located at East 69th Street and St. Clair Avenue, covered under one roof 155,000 square feet.

But to return to the opening ceremony of the Central Viaduct. Mayor Brenton D. Babcock accepted the bridge for the city. After this, the parade moved across the new bridge, to Central Avenue, turning north down Ontario Street to City Hall on Superior, where the city officials greeted the marchers. That evening, at the Hollenden Hotel, officials, governors, councilmen, congressmen, and distinguished citizens dined in grand style. After a banquet the assembly was addressed by Mayor Babcock, who read telegrams from illustrious persons unable to attend, among them being John D. Rockefeller, and the President of the United States. The bridge was described and presented to the city by Mr. Walter P. Rice, the City Engineer, the Honorable Joseph Foraker who spoke for the State of Ohio; Mr. M.M. Hobart for the city of Cleveland; Mr. James Curtiss for the Cleveland Short Line Railway; F.C. McMillan spoke for the militia; the Honorable George W. Gardner for Cleveland’s industries; and the Honorable W.W. Armstrong on behalf of the press.

But civic pride rose to even greater heights than it did in these oratorical speeches. It inspired poetry from the pen of a young newspaperman, W.R. Rose of The Sun and the Voice, who late joined the staff of the Plain Dealer, wrote and epic poem that described the old battle between the South and West Sides, of the city. (His son, W.G. Rose, wrote Cleveland, The Making of a City.)

Curtius at the Bridge

The doughty West Side fathers-

By all the gods they swore,

That Curtius; bridge should never span

The smokey valley o’er;

They polished up their armor,

The bright war-paint they spread,

With sullen roar they rudely swore

To paint the South Side red.

Curtius is, of course, James Curtiss, the councilman who introduced the original resolution for the bridge. The poem proceeds to describe in bloody images how Curtius and Caius Caskey (another councilman named A.C. Caskey, also active in pushing the construction of the viaduct) defended their bridge and finally quelled all resistance from the opposition, saving the structure for the city. The verse, is, of course, a parody on the classic “Horatius at the Bridge”, familiar to every schoolchild of that time.

They gathered in the Forum,

A dark and vengeful crowd,

And scoffed upon the Curtius’ bridge

In speeches fierce and loud;

They claimed the bridge would ruin

Both Pearl Street and Lorain,

And so they fought the project

With fourfold might and main.

Up rose Horatius Curtius

And spake in haughty tones:

“Oh, craven dough heads that ye are,

I’ll hold the bridge alone!

Now who will stand beside me,

Has no one got the sand?

“I have,” cried Caius Caskey,

“Upon the right I’ll stand.”

In columns dark and serried

On came the angry foe,

Alone stood Curt and Caskey,

To stem the warlike flow.

Upon the Heights, affrightened,

Ten thousand eyes looked down,

And watched in nervous dread to see

Who’d wear the victor’s crown.

Loud laughed the West Side legions

To see the little band,

And cried, “You soon, must bite the dust

As on your heads you stand.’

“But loudly fearless Curtius

Cast back that laugh on scorn,

“O me an’ Caskey here will make

You wish you ne’er were born!”

Fierce waged the awful battle,

A score against but two.

Until the Teuton Herman dropped

And from the fight withdrew;

Bold Quintius Morrison was next

To beat a swift retreat,

And C. Pompilus Ford arose

To say that he was best.

Like zigzag lightnings flying

The swords of Cask And Curt,

Where ‘er theyfell, they left a mark

And made the crimson spurt.

Like beaten wolves back shrank the foe,

In sullen tones they raved,

Until they scattered in dismay

And Curtius’ bride was saved!

In coming generations when

Our chidren’s children tell

The famous stories of the past –

The tales they love so well –

With cheering and with laughter

One deed they’ll keep alive,

How well brave Curtius saved his bridge

In eighteen eighty-five.!.”[25]

But, spite of the gay dedication and festive spirit, the new viaduct soon became to be known as the “tragic” bridge It had not been long use before disaster struck. On a cold, dark and foggy night, 16 November 1895, a crowded streetcar plunged into the river. The draw had been opened to permit the passage of a tug, and the streetcar approached the span at a high rate of speed. A safety switch 150 feet from the draw was not working; parts of it had been removed for repairs. The motorman and one passenger saved themselves by jumping, but sixteen passengers and the conductor drowned. On 25 May 1914, disaster struck again; a section of the viaduct’s wooden floor was burned during a fire in the lumber yard of Fisher and Wilson in the Flats below the bridge. Consequently the bridge was out of commission for a year. Then, later, an iron stairway from the lower level to the deck of the viaduct collapsed. A man on the stairs narrowly escaped death when his fall was broken by wires..”[26]

In January of 1941 the Central Viaduct was condemned and closed to traffic. The residents of the area fought for its preservation. They lost, however, for the bridge was torn down, and its five hundred tons of steel were converted into scrap during World War II.

The Inner Belt Bridge

Cleveland had to wait almost twenty years for a new bridge on the old Central Viaduct right-of-way. Delays were caused by war, by consideration of Cleveland’s traffic needs, and by the need of long-range planning. It was not until 15 August 1959 that a new bridge was opened at a dedication and ribbon-cutting celebration.[27]

The early replacement of this bridge was postponed as it was to become a part of the Inner Belt Freeway System. This freeway movement received its initial impetus in 1940, when the electorate of Cuyahoga County approved a bond issue in the amount of $4,500,000 to purchase right-of-way for six isolated freeway projects. These projects as contemplated were to include portions of Willow, Lakeland, Newburgh and Jennings Freeways (as they were originally named), a section of Chester Avenue from East 55th Street to Eat 93rd Street, and a bridge over Rocky River to connect West Lake Road. In July 1940, the Ohio Department of Highways established a planning office In Cleveland to develop construction plans for these projects. These freeways were more or less isolated, but the need for a comprehensive freeway plan soon became apparent. Early in 1941, the Public Works Committee of the Regional Association of Cleveland established the Expressways Highway Subcommittee for the purpose of planning an express highway system in Cleveland metropolitan area. This subcommittee was composed of engineers representing the Planning Office of the Ohio Department of Highways, the Cuyahoga Planning Commission, the Cleveland City Engineer’s office, the Cleveland City Planning Commission and the Regional Association of Cleveland. This committee met weekly or bi-weekly for nearly three years to produce a freeway plan that would meet the immediate and future needs of this area. During that time the committee received cooperation and assistance from the Cleveland Transit System and the Cleveland Traffic Bureau.

In April of 1944 the committee submitted its report. “Express Highway Plan for the Cleveland Metropolitan Area”, to the Public Works Committee. The Regional Association of Cleveland, in November of 1944, published the report labeled “Publication Number 19.” The plan advocated an Inner Belt and an Outer Belt with a number of radial freeways. It also incorporated the six freeway projects included in the County Bond issue of 1940. Although adjustments and changes have had to be made in the interim, the basic concept of belt freeways was retained in Cuyahoga County. Numerous delays were encountered. An expediting committee was formed in 1947, consisting of three members representing the Planning Office of the Ohio Department of Highways, the Cuyahoga County Engineer’s Office, and the City Planning Commission.

On 23 October 1953, the city retained Howard, Needles, Tammen and Bergendoff as consulting engineers to prepare preliminary plans for the approaches to the Central Viaduct, for the interchange with the Willow Freeway (commonly referred to as the Central Interchange), and for preparation of detailed contract plans for the Inner Belt from Fairfield Avenue to East 22nd Street which includes the Viaduct, it approaches, and the central interchange.

Cleveland’s Inner-Belt Freeway forms a partial loop around the central business section, connecting with Memorial Shoreway near East 30th Street. The freeway runs southerly from the shoreway, passing under Lakeside, Hamilton, St. Clair, Superior, Payne and Chester Avenue. Curving to the southwest, it passes under Euclid, Cedar Avenue and East 22nd Street; and then it rises to become elevated as it goes over East 13th Street. Access to the Inner Belt Bridge from central; business district is furnished by ramps from Broadway, Carnegie Avenue and East 9th Street; exit ramps are provided to Broadway for either eastbound or westbound traffic. Access on the southwest side is provided by a ramp from Fairfield Avenue, and exit ramps lead to Fairfield and Abbey Avenues.

The bridge spans the river, and numerous tracks belonging to the Erie, Penn-Central, Chessie System and the Norfolk and Western, and to the Cleveland Shaker transit systems which now are part of RTA. It crosses over Broadway Avenue, Commercial Road, Canal Road, University Road, Abbey Avenue, and a number of streets in the valley. It spans the former Nickel Plate Freight House, the N&W Railroad trestle, the sand and gravel plant of Cleveland Builders Supply Company, and several local streets.

The Inner Belt Bridge is one of the major bridges in the country. It is the widest bridge ever built in Ohio, and the $8,132,200 contract for the construction of the superstructure which forms the central part of the viaduct was the largest single such contract ever awarded by the Highway Department. It has eight traffic lane (four in each direction) and can accommodate a traffic volume of 95,000 vehicles per day. Three-foot safety walks are provided on each side of the bridge for emergency pedestrian use. The overall length of the bridge is 4,223 feet (eight-tenths of a mile), and it is 116 feet, 3 inches wide. The central portion of the viaduct consists of 2,721 feet of cantilever deck-truss construction, with a reinforced concrete deck and asphaltic concrete wearing surface. The deck-type construction provided substantial savings in pier cost, resulting in a pleasing appearance, and presented minimum interference with driver’s vision. Vertical clearance was not a problem here.

The bridge has two main longitudinal trusses (which vary in depth from 21 feet 6 inches in suspended sections to 68 feet at the piers) parallel to each other and 90 feet apart. There are seven truss spans, varying in length from 226 feet 6 inches to 400 feet. The reinforced deck slab is supported by longitudinal stringers. These rest on transverse floorbeam trusses, which are spaced at 25-foot intervals and span the 96 feet between the two main trusses. High-strength manganese steel was used for many of the large truss members, for it was more economical than the customary structural carbon steel.

The approach spans and their connections with the central portion of the bridge are also interesting. The western approach comprises about 750 feet of embankment construction for ramps, and 371 feet of viaduct construction. For the four spans in this section, relatively deep continuous deck plate-girders with framed-in floor beams and stringers were used.

On the east approach conditions were far more difficult; grades and vertical clearance were extremely critical, and spans had to be longer. This approach consists of 1,131 feet of viaduct construction, with additional embankment construction for the ramps. To clear the New York, Chicago and St. Louis Railroad (N&W) Freight Terminal and the adjacent roadway and tracks, a span of 239 feet was needed, and a span of 243 feet was required

for one of two of the access ramps. Because of the limited vertical clearance, multiple deck plate-girders of high-strength steel and of relatively shallow depth were used, instead of the girders with floor systems, as one on the west approach; and the deck slab was placed directly on the girders. Even with this shallow girder construction, the bottom of the girders clears the freight house by less than one foot.

The piers for both approaches are rigid frames of reinforced concrete. The abutments, also of reinforced concrete, are the spill through type [Figure XI].

Supervision of construction for all parts of the bridge was by the State of Ohio Department of Highways. The bridge is a part of the National System of Interstate and Defense Highways and thus qualified for 90 percent federal aid, the city and state and paying 5 percent each.

From this description it can readily be seen that this bridge is indeed an important and major achievement in bridge design, a dramatic change from the old 1880 Central Viaduct. The contrast can be seen by comparing this new bridge with the Abbey Avenue Bridge. And it can also be seen that the building of a modern bridge of major proportions is a complicated affairs.

- Oliver P. Baldwin, in Bridges of Cleveland and Cuyahoga County, pp. 38-39. ↵

- F.T. Wallace, "Viaduct Reflections" (Cleveland, 1879). ↵

- Loc. Cit. ↵

- Wood, "The Old Detroit-Superior Viaduct," p. 19. ↵

- Ibid., p. 20 ↵

- Ibid., pp. 21-22 ↵

- Nathan P. Payne, Message to the City Council (delivered on April 11, 1876). ↵

- Wallace, "Viaduct Reflections" ↵

- Jim Didas, "Old Superior Viaduct Waiting for its Doom," in Cleveland Press (December 20, 1971). ↵

- Quoted from B.F. Morse’s report, see Appendix C. ↵

- Stanley L. McMichael, "The New Detroit-Superior High Level Bridge", in Bridges of Cleveland and Cuyahoga County, p. 7. ↵

- Henry Grattan Tyrrell, "The Bridges of Cleveland," in The Ohio Architect, Engineer, and Builder (1915) p. 5. ↵

- "Builders of the New High-Level Bridge," in Bridges of Cleveland and Cuyahoga County, p. 37. ↵

- Ralph E. Robinson, "Reconstruction of the Detroit-Superior Bridge," in The Ohio Engineer (June, 1986) pp. 6-7. ↵

- "Civic Brevities", in The Clevelander (December 19, 1927). ↵

- Wilbur J. Watson, A Decade of Bridges: 1926-1936 (J.H. Jansen, Cleveland, Ohio, 1937) pp. 11-26. ↵

- "Maskers Dance at Lorain Span Fiesta", in Cleveland Plain Dealer (November 10, 1932.). ↵

- Dan F. Bradley, "The Bridge As Sermon in Steel," in Cleveland Plain Dealer (December 8, 1932). ↵

- Rose, W.G. p. 356. ↵

- For a detailed study of this investigation see William J. Eney, "Model Analysis of Continuous Girders," in Civil Engineering, II, 9 (September, 19410 521-523. ↵

- Howard Beaufait, Cleveland News (March 8, 1939). ↵

- Data taken from Stanley L. McMichael’s article, "Other Important Bridges of Cleveland." in Bridges of Cleveland and Cuyahoga County, p. 33. For information on the Abbey Street Bridge, see Thomas Palko’s report in the Haer Inventory (August 11, 1975). ↵

- City, Engineer’s Report of 1914 ↵

- Rose. W.G., p. 287. ↵

- The account of the Central Viaduct, written by Sara Ruth Watson, published in The Plain Dealer on December 4 10, 1938, in commemoration of the fiftieth, anniversary of the bridge. ↵

- See Henry Grattan Tyrell’s article, "The Bridges of Cleveland," p. 6 ↵

- The authors are greatly indebted to Ralph E. Robinson of Howard, Needles, Tammen and Bergendoff for information on the Inner Belt Viaduct. ↵